Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

I. Main Application Scenarios of the Brake Pad Hot Pressing Machine

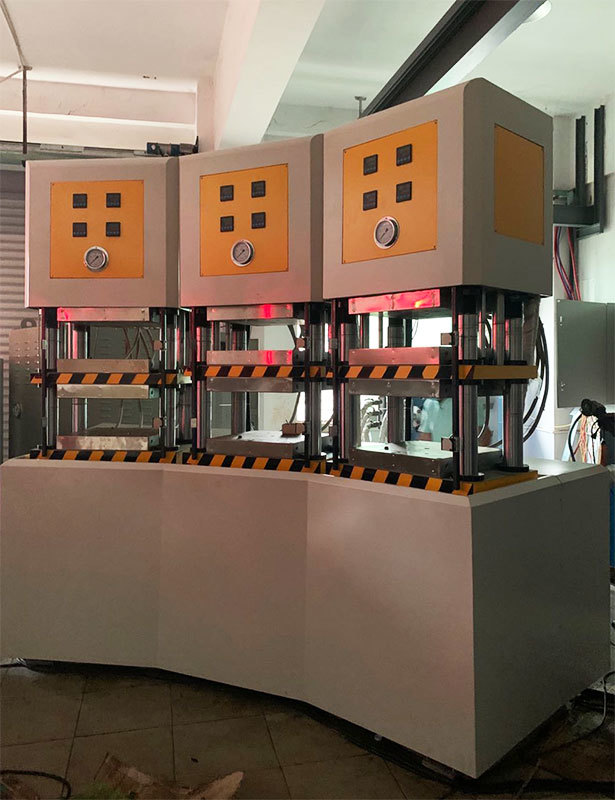

The brake pad hot-pressing machine is the core equipment for brake pad manufacturing, with applications spanning automotive and related industries, specialized transportation, scientific research experiments, and more. Its primary value lies in using high-temperature, high-pressure technology to ensure consistent performance and dimensional accuracy of brake pads.

1. Automotive Manufacturing (Core Application)

- As a critical component of automotive braking systems, the quality of brake pads directly impacts driving safety. The hot-pressing machine precisely controls temperature, pressure, and time to produce brake pads—such as disc and drum brake pads—with exact shapes and consistent dimensions, meeting automakers' stringent requirements for high wear resistance and superior heat tolerance (e.g., maintaining a stable friction coefficient even when temperatures exceed 600°C during braking).

- Supports mass production, enhancing the efficiency of automotive assembly lines, and is adaptable to the braking system requirements of various vehicle models, including conventional gasoline cars and new-energy vehicles.

2. Automotive Repair and Replacement Market

- As vehicle mileage increases, brake pads inevitably wear down and require regular replacement. The hot-press molding machine addresses this need by enabling efficient production—capable of churning out hundreds of brake pads per day on a single unit—while significantly reducing costs. This innovation provides repair shops and car owners with high-quality, affordable brake pads that meet the market demand for quick replacements, allowing service centers, for instance, to swiftly stock up on pads tailored to specific vehicle models.

3. Specialized Transportation Sector

- Aerospace: Brake pads designed for high-temperature resistance—capable of withstanding temperatures exceeding 1000°C, such as during aircraft braking—and requiring exceptional strength. Thermal compression molding machines utilize advanced materials like carbon-ceramic, combined with precise process control, to ensure the brake pads maintain stability under extreme heat and achieve exacting shape accuracy, thereby meeting the stringent aerospace industry standards.

- Rail transit systems—such as subways and high-speed railways—require brake pads that are both wear-resistant and corrosion-proof. The equipment features a pressure-balancing design to prevent material misalignment, ensuring a precise fit between the brake pads and the braking system—and ultimately guaranteeing safe operation.

- Marine and Construction Machinery: Brake pads for large machinery such as ships and excavators must withstand wear and high temperatures. Heat-pressed molding machines enhance the durability of brake pads by employing a densification process that reduces air gaps within the material, ensuring optimal performance even in harsh operating conditions.

4. Research and Experimental Fields

- Researchers use a hot-pressing machine to develop brake pad materials—such as new friction materials and eco-friendly options—by precisely controlling pressing parameters (temperature, pressure, and time) to test the materials' friction coefficients, wear rates, and other key performance characteristics, ultimately providing data-driven insights for brake pad improvements.

- Supports small-batch customization for experimental validation (e.g., testing the performance of different materials under extreme conditions).

II. Core Features of the Brake Pad Hot Pressing Machine

The advantages of the brake pad hot-pressing machine lie in its **precision, efficiency, environmental friendliness, and strong adaptability**, with features centered around process stability and equipment reliability.

1. Precise control ensures product quality

- Temperature Control: A high-precision temperature control system (e.g., with an accuracy of ±1°C) is employed to ensure uniform heating of brake pad materials—such as friction material and steel backing—preventing localized overheating or incomplete vulcanization (e.g., when rubber components fail to fully cure).

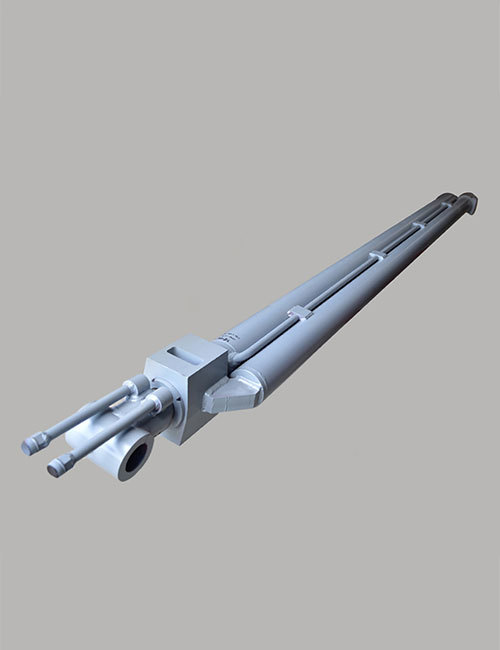

- Pressure Control: Utilizing a hydraulic system or servo closed-loop system, the process delivers stable, high pressure—up to hundreds of tons—to ensure thorough material filling within the mold, minimize internal defects such as bubbles and cracks, and enhance the density of brake pads (e.g., density > 2.5 g/cm³).

- Time Control: Supports multi-stage time settings (heating - vulcanization - pressure holding), ensuring complete curing of the brake pads (e.g., achieving a vulcanization degree >95%) and maintaining stable friction performance.

2. Efficient production, reduced costs

- Batch production capability: Utilizing an automated loading/unloading system and continuous production mode, a single piece of equipment can produce anywhere from hundreds to thousands of brake pads per day on average, significantly boosting productivity—up by more than 30% compared to traditional methods.

- Automated operation: Equipped with a PLC control system, it supports program storage (e.g., storing over 50 sets of process parameters), minimizing manual intervention and reducing labor costs (e.g., operators only need to monitor equipment status).

3. Energy-efficient and environmentally friendly, aligning with green production

- Closed-loop control system: Reduces energy consumption (e.g., by more than 20% compared to traditional equipment) and lowers carbon emissions during the production process.

- Application of eco-friendly materials: Utilizing asbestos-free and low-heavy-metal materials to minimize harmful emissions (e.g., complying with ROHS standards), ensuring compliance with global environmental regulations—such as the EU market’s stringent environmental restrictions on brake pads.

4. Highly adaptable, meeting diverse needs

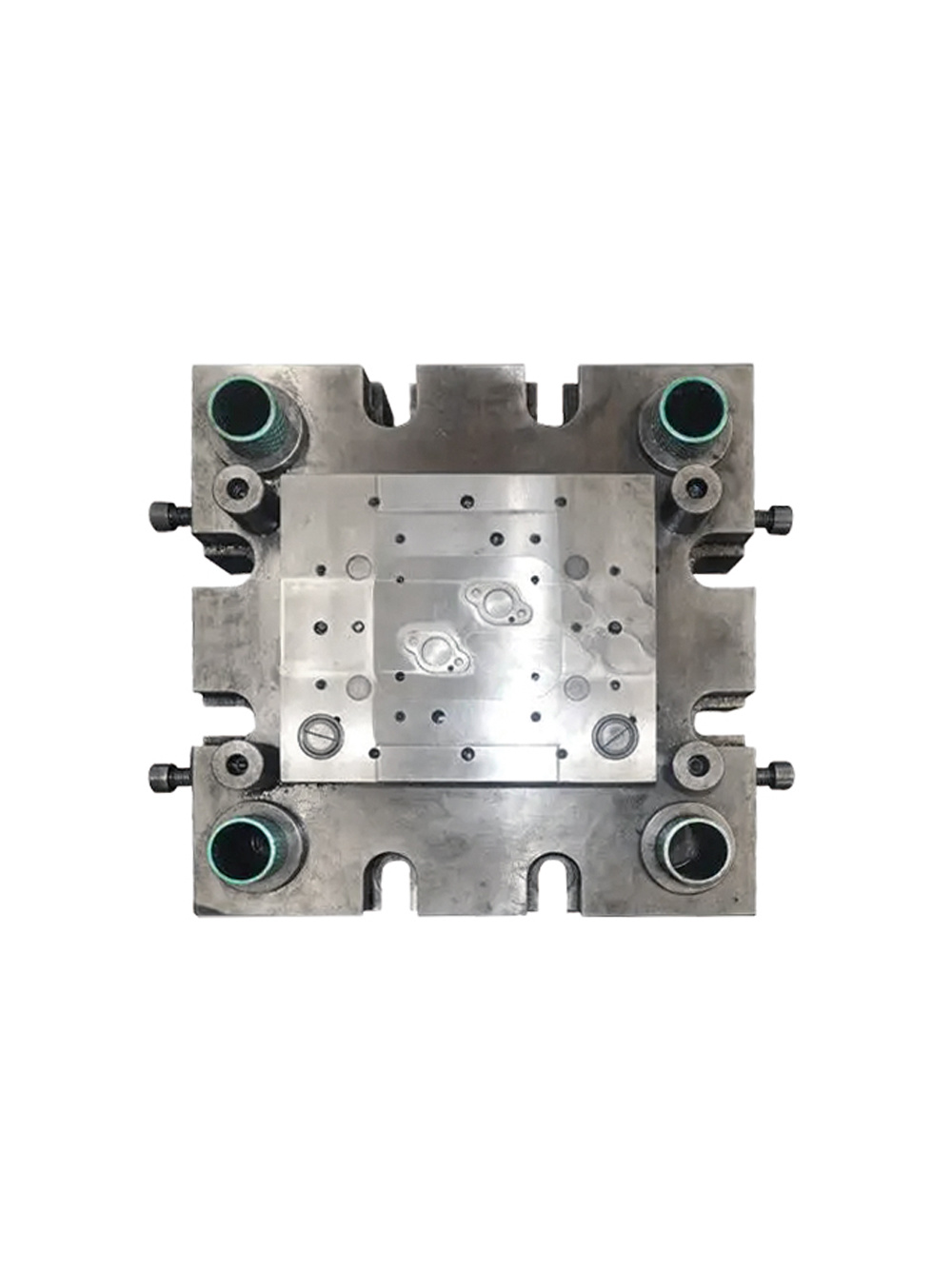

- Modular design: Easy to maintain and upgrade (e.g., different types of brake pads can be produced simply by replacing the mold), supporting the production of various brake pad types, including disc, drum, and ceramic brakes.

- Key to mold design: The mold must be precisely manufactured according to the shape and dimensions of the brake pad (with tolerances less than 0.02mm), ensuring that the finished brake pad perfectly matches the braking system—specifically, achieving a bonding strength between the steel backing and friction material exceeding 10 N/mm.

5. Safe and reliable, easy to operate

Pressure-balanced design: Prevents material shifting during molding and ensures consistent brake pad shapes (e.g., edge deviation < 0.5mm).

Real-time Monitoring and Alarming: Equipped with sensors and an alarm system, this system continuously monitors parameters such as temperature and pressure to prevent operator errors—such as automatically shutting down the equipment if pressure exceeds safe levels—thereby ensuring the safety of both the equipment and personnel.

Summary

The brake pad hot-pressing machine is the core equipment in brake pad manufacturing, with applications spanning from everyday automotive maintenance to aerospace industries. Its key value lies in ensuring consistent performance and quality of brake pads through precise control and highly efficient production processes. As emerging fields like new energy vehicles and intelligent driving continue to grow, the equipment will further evolve toward smarter technologies—such as AI-driven process optimization—lighter designs that reduce overall equipment weight, and more eco-friendly solutions, including the adoption of energy-efficient heating methods. These advancements aim to meet the ever-increasing demands of the market.

Main performance and features of the equipment:

a. Automatic mold ejection feature;

b. Side-cylinder clamping and leak-proof function;

c. Precise temperature control function;

d. Multi-stage pressure control, with a hold time set separately for each pressure stage;

e. Multiple venting function;

f. Scheduled heating function;

g. Menu-based save/restore functionality for product production data;

h. 1000-second ultra-long holding pressure function;

I. Heating method: Electric heating tube

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Brake Pad Hot Press Molding Machine

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.