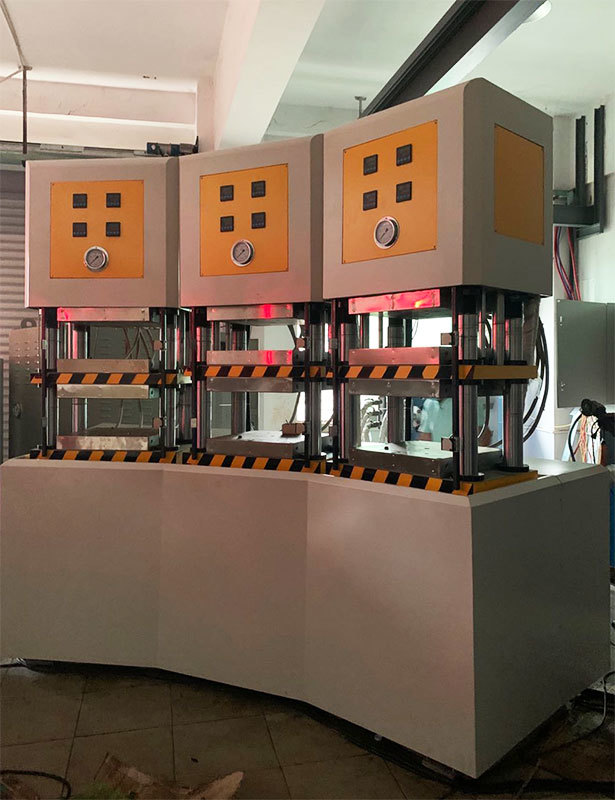

Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

1. Servo motors, paired with a high-precision oil pump, enable segmented control of pressure, speed, and exhaust.

1. Servo motors, paired with a high-precision oil pump, enable segmented control of pressure, speed, and exhaust. 2. Precise control of displacement, velocity, and pressure—adjustable at will on the industrial touchscreen;

3. Provide remote online services, with machines automatically alerting users to faults and scheduling maintenance.

4. Work position, speed, and pressure can be infinitely adjusted;

5. Rapid response, high pressure, and precise positional repeatability;

6. 12 hours of continuous operation require no cooling oil temperature adjustment;

7. Pipes and fittings comply with the SEA international standard to prevent oil leaks;

8. Highly efficient with multiple built-in protections, resulting in an extremely low failure rate;

9. The low-pressure intelligent mold-clamping system features automatic foreign-object detection and feedback functionality, ensuring mold safety.

2. Displacement Accuracy: The displacement repeatability can reach ±0.03 mm;

3. Highly Efficient and Energy-Saving: Operates at high speed, achieving energy savings of up to 50%.

4. Flexible Pressing: Operates smoothly with no impact or vibration to the equipment;

7. The slider mechanism allows for adjustable fast-down speeds ranging from 50 to 175 mm/s.

8. The slide mechanism allows for adjustable forward feed speed ranging from 5 to 20 mm/s (adjustable as a percentage);

9. The slider mechanism features an adjustable lifting speed of 50–150 mm/s.

Previous entry:

Next:

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Four-column precision hydraulic press

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

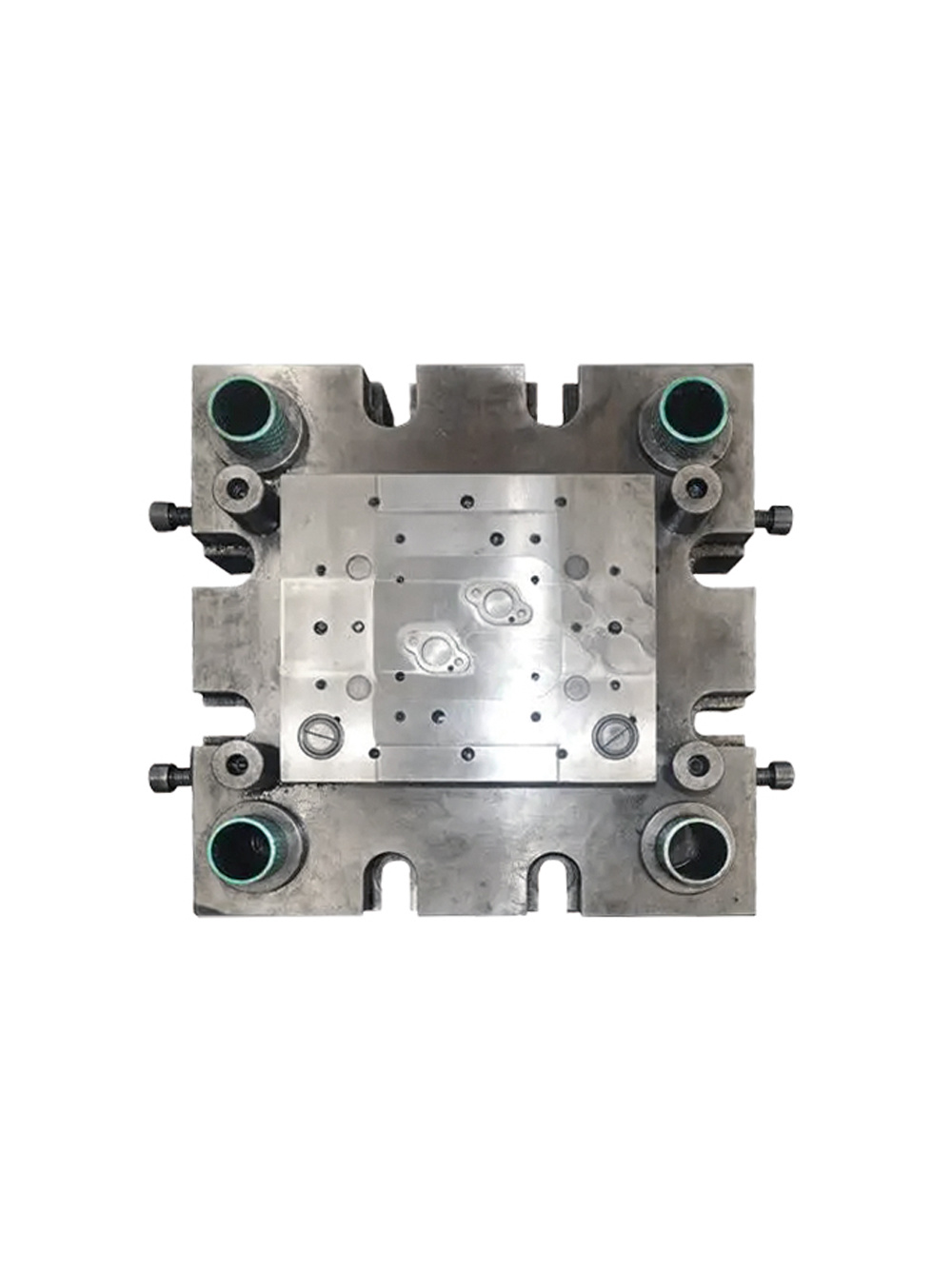

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

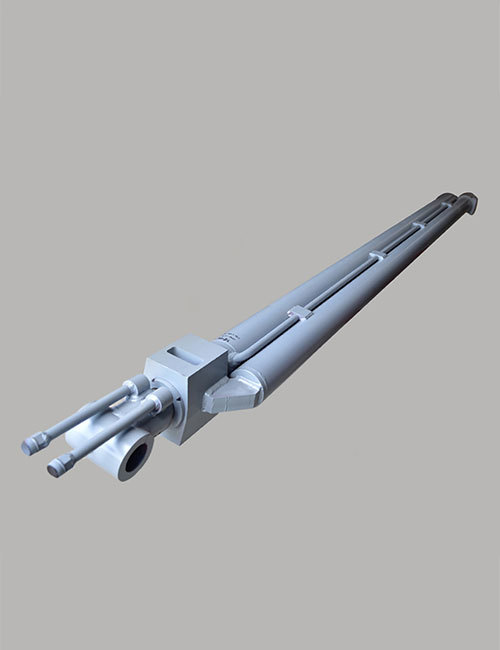

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.