Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

I. Core Application Areas

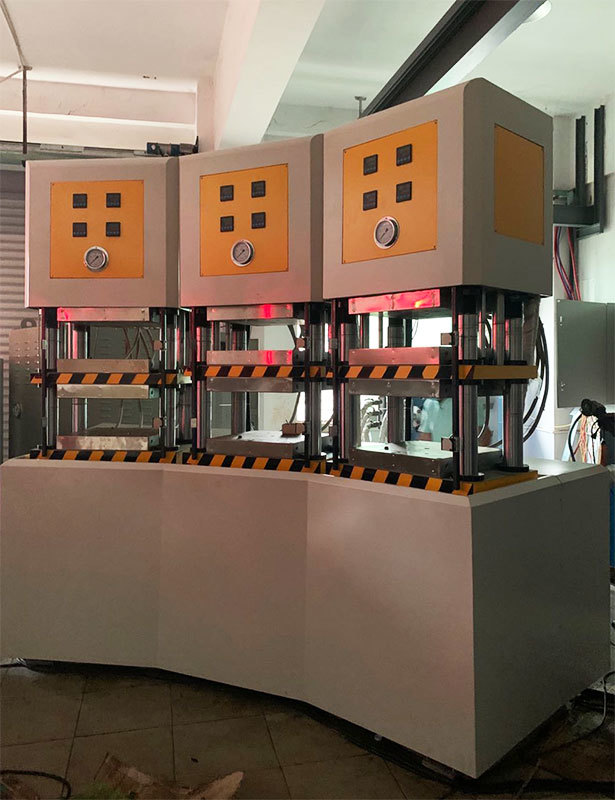

The frame-type composite material hot press is a critical piece of equipment for large-scale, high-tonnage, mass-production composite molding. Combining the "high rigidity of its frame structure," the "efficiency of multi-layer hot press plates," and the "reliability of precise control," it is widely used in the following high-end industries:

1. Aerospace sector (core high-value applications)

The frame-type structure boasts superior resistance to eccentric loading (with rigidity outperforming the four-column type), making it ideal for manufacturing large-sized load-bearing components such as aircraft wing skins, fuselage sections, satellite supports, and rocket fairings. Multi-layer hot press molds enable the high-volume processing of carbon fiber prepregs or composite material blanks, ensuring both dimensional accuracy—within ±0.05 mm—and exceptional mechanical properties, including tensile strength ≥500 MPa and stiffness ≥20 GPa. This capability perfectly meets the aerospace industry’s extreme demands for "lightweight yet ultra-strong" materials. For instance, a specific model of aircraft wing component requires forming using a 1,500-ton frame-type multi-layer hot press machine, capable of producing two parts per layer while achieving an impressive hourly output of 8 to 10 units.

2. Automotive Manufacturing Industry (Demand for Scalable Lightweight Solutions)

Addressing the core automotive need for "weight reduction and energy efficiency," frame-type multi-layer hot presses are used to mass-produce composite structural components—such as body frames, battery pack housings, door panels, and chassis parts. This frame-based design delivers stable, high-pressure capabilities (up to 2,000–5,000 tons), ensuring thorough compounding of carbon fiber or glass fiber with resin matrices while preventing delamination or air bubbles. Additionally, the multi-layer configuration (4–12 layers) significantly boosts production capacity—achieving 3 to 5 times higher output compared to single-layer machines—thus meeting the automotive industry's demand for "scalable manufacturing." For instance, a certain new-energy vehicle manufacturer employs a 10-layer frame-type hot press capable of producing 30 battery pack housings per hour.

3. Sports Equipment Manufacturing (High-End Customization Needs)

The framework-style structure offers precise control capabilities—pressure can be maintained within ±0.1 MPa, and temperature within ±3°C—making it ideal for manufacturing high-end sports equipment such as carbon-fiber bicycle frames, golf clubs, skis, and tennis rackets. Multi-layer hot-pressing plates allow simultaneous molding of multiple components (e.g., producing two bicycle frames per layer), significantly reducing per-unit production costs. Meanwhile, the exact temperature and pressure control ensures consistent mechanical properties across all products—such as achieving an impact-resistance tolerance of less than 5% for bicycle frames—thus meeting the tailored needs of professional athletes.

4. Industry and New Energy Sector (High-Demand for Large-Scale, High-Strength Applications)

The frame-type structure ensures stability—free from swaying or uneven loading—making it ideal for producing large-scale industrial composite components such as wind turbine blades, 5G base station antenna domes, high-pressure vessels, and tunnel-boring machine cutters. Its multi-layer design (6–12 layers) significantly boosts production efficiency; for instance, carbon-fiber skins for wind turbine blades can be manufactured at a rate of 4 to 6 pieces per hour. Moreover, the use of high-temperature, high-pressure conditions—ranging from 200–300°C and pressures of 1,000–3,000 tons—guarantees that the final components achieve exceptional strength, with tensile strengths of ≥300 MPa in applications like wind turbine blades. This meets the growing demand in the new energy and industrial sectors for "large dimensions combined with ultra-high reliability."

II. Core Features (The Combined Advantage of a Framework-Based and Multi-Layered Approach)

1. Framework Structure: High Rigidity and Resistance to Lateral Loads

It adopts a rectangular frame/Gantry frame structure (welded from steel plates), offering excellent overall rigidity and superior resistance to eccentric loading—up to 20%-30% higher than four-column types. This design is ideal for handling high-tonnage presses (1000–5000 tons) and large-sized products, such as wind turbine blades exceeding 10 meters in length. The frame-style construction ensures smooth slider movement without any shaking, effectively preventing mold damage or workpiece deformation caused by uneven loading.

2. Multi-layer Design: Efficient Mass Production with Uniform Heat Distribution

Equipped with 4-12-layer hot press plates (each layer features independent temperature control), this machine can simultaneously apply pressure and heat to multiple composite material preforms—such as carbon fiber prepregs and glass fiber-reinforced plastics. Its production capacity is 3 to 5 times higher than that of single-layer machines. The hot press plates are precision-ground using imported tool steel, ensuring minimal thermal deformation (<0.1mm). Thanks to PID-based intelligent temperature regulation, the system allows for precise adjustments from room temperature up to 300°C, with a temperature accuracy of ±3°C per layer. This ensures uniform heating across all workpieces, preventing uneven resin flow or curing defects caused by temperature variations.

3. Composite Material Compatibility: High-Temperature, High-Pressure Conditions and Defect Control

Addressing the **"resin flow + fiber orientation"** requirements for composite materials such as carbon fiber and glass fiber, we offer:

- High-Temperature Control: Temperature can reach 200–300°C (suitable for curing temperatures of epoxy resins, phenolic resins, and more), with an accuracy of ±3°C.

- High-pressure output: Up to 1000–5000 tons (ensuring resin fully fills fiber gaps, preventing bubbles or delamination);

- Resin Loss Control: By implementing multi-stage pressure settings—such as "pre-pressure, main pressure, and holding pressure"—resin loss during the molding process is minimized (resin content error < 2%).

4. Intelligent Control: Servo Closed-Loop System with Process Flexibility

Equipped with a servo closed-loop control system, the equipment enables precise control of pressure (±0.1 MPa), temperature (±3°C), and displacement (±0.02 mm). It supports flexible, multi-segment settings for both pressure and stroke, such as "fast descent—slow pressurization—pressure-holding curing—rapid return," making it suitable for various composite material molding processes—for instance, the "heating → pressurization → curing → cooling" sequence used for carbon fiber prepregs. Additionally, some models can store over 100 sets of process parameters, including mold numbers, temperature profiles, and pressure curves. When switching between products, operators simply recall the corresponding program, significantly reducing mold-change time by more than 30%.

5. Energy Efficiency and Safety: Balancing Performance with Protection

- Energy efficiency: The servo system only performs work when the cylinder is in operation, eliminating overflow losses. This results in energy savings of up to 30%-50%, while also maintaining low operational noise levels (below 70 dB).

- Safety: Equipped with a highly sensitive through-beam safety light curtain (covering the equipment’s opening area), three-sided guardrails, dual-hand operation buttons, and an emergency stop button to ensure operator safety—and prevent injuries or equipment damage caused by accidental misoperations.

Summary

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control" making it a critical enabler for "lightweight + high-strength" products in industries such as aerospace, automotive manufacturing, and sports equipment. As composite materials like carbon fiber and glass fiber continue to gain widespread adoption—driven by sectors such as the automotive industry, where annual growth in composite material usage exceeds 15%—this equipment will increasingly serve as the "mainstay force" in shaping advanced composite components.

Main performance and features of the equipment:

a. High temperature control accuracy of ±2°C;

b. The thermal plate temperature difference can be as low as ±5°C at best;

c. The hot plate can achieve a flatness accuracy of up to ±0.03 mm;

d. Multi-stage pressure control, with a hold time set separately for each pressure stage;

e. Multiple venting function;

f. Multi-stage temperature control;

g. Scheduled heating function;

h. Menu-based save/restore functionality for product production data;

I. Three-stage pneumatic inflation function;

j. 1000-second ultra-long holding pressure function;

k. Heating methods: Optional electric heating tube heating or mold temperature controller heating;

1. Optional vacuum function;

m. Module Configuration: 1–10 layers customizable;

Next:

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Frame-type Composite Material Hot Press Molding Machine / Hot Press

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

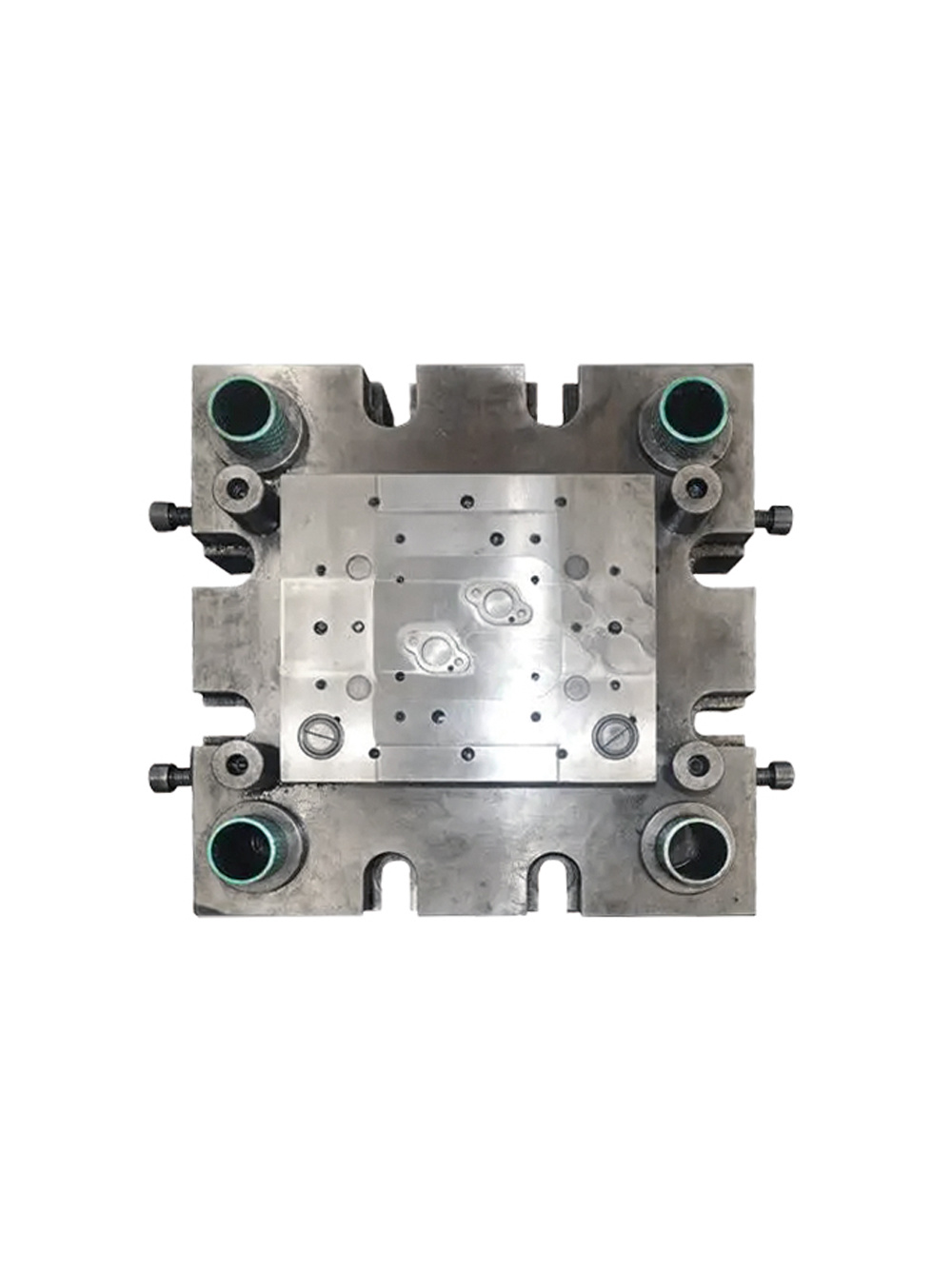

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

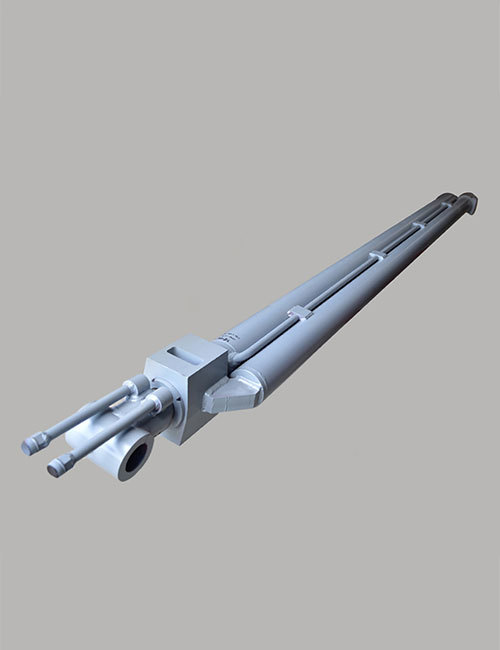

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.