Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

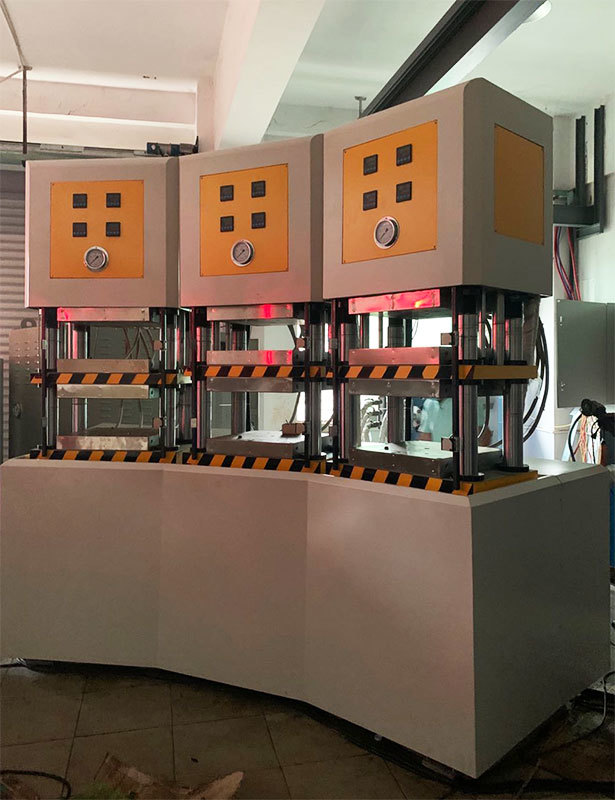

Automatic Hydraulic Press for Magnetic Materials

1. Overview of the Magnetic Material Press:

The fully automatic magnetic material forming hydraulic press is primarily designed for the mass production of high-performance rare-earth bonded permanent magnet products through compression molding. It is also the ideal molding equipment for a wide range of precision powder components. The main unit features a high-precision rail-frame structure with a floating cavity design, paired with synchronized upper and lower hydraulic cylinder systems.

This machine boasts a compact layout, a low center of gravity, and exceptional stability, rigidity, and precision. A standout feature of its hydraulic system is that, during the pressing process, the lower cylinder only begins to move after the upper cylinder reaches a predetermined pressing force—enabling bidirectional compression. This unique mechanism ensures uniform product density, resulting in high-performance magnets. Additionally, the press incorporates a protective demolding function.

Fully Automatic Magnetic Material Press Servo Energy-Saving Upgrade Solution

2. Machine Components:

1: Host:

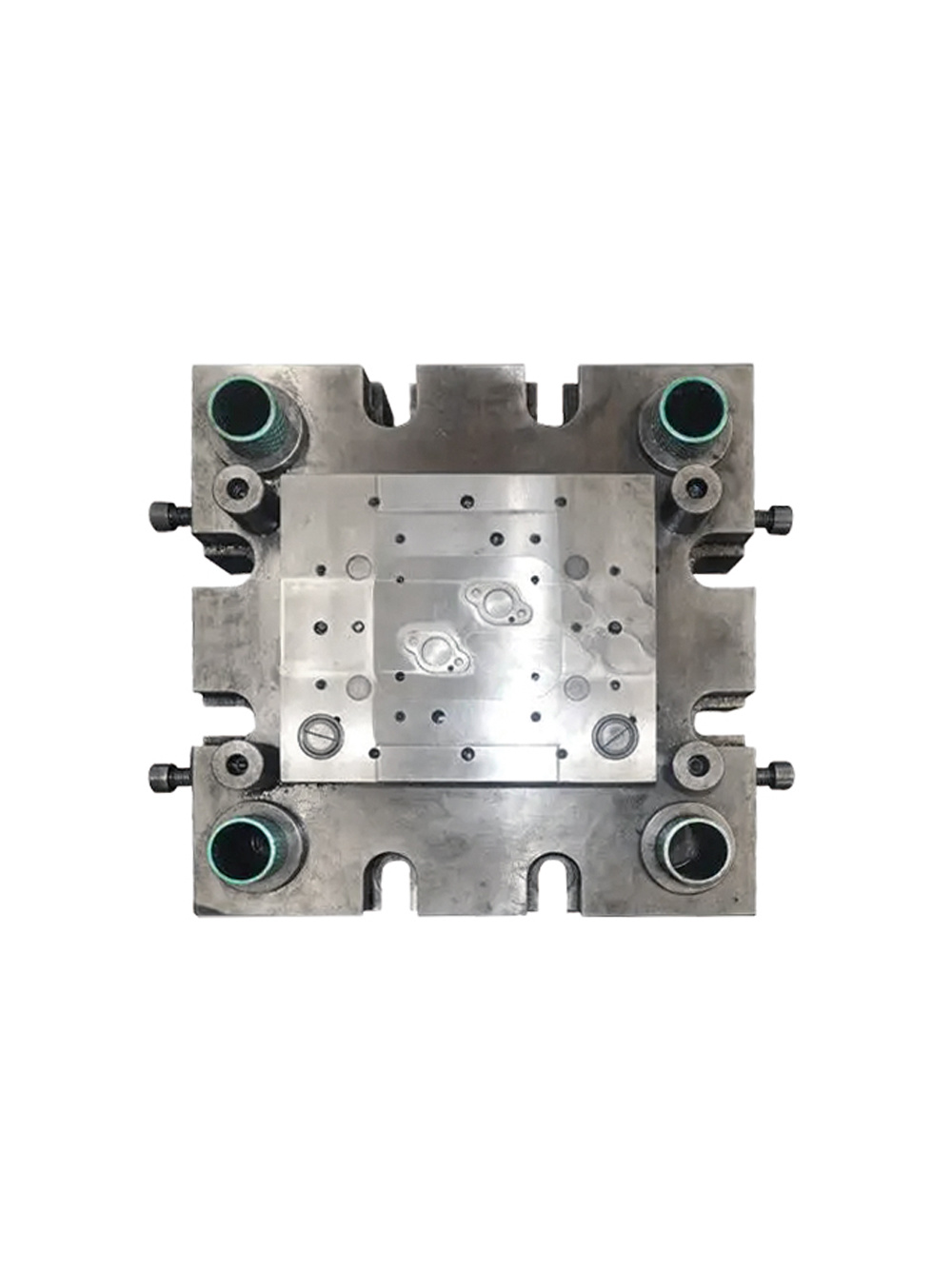

(1) Featuring a high-precision rail-frame design, equipped with a main cylinder, lower cylinder, fluid charging unit, and upper limit device.

Including the lower limit device, etc. The workbench features a wide surface area, allowing for the installation of various types of multi-cavity molds.

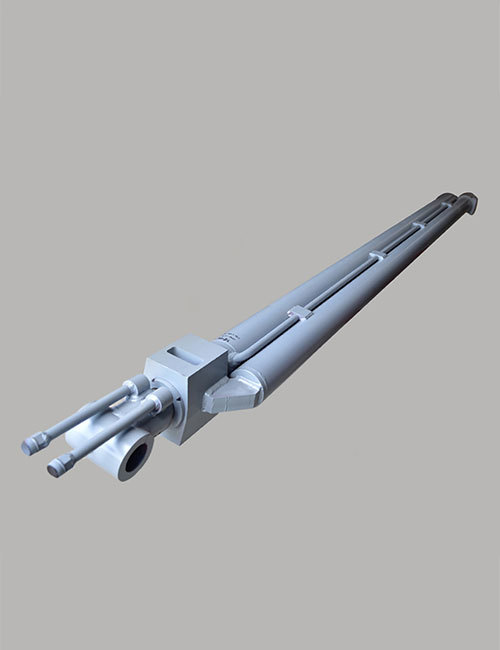

(2) Both the upper and lower cylinders feature integral forged cylinder barrels.

(3) The piston rods of the machine cylinders all undergo surface heat treatment followed by hard-chromium plating.

2: Hydraulic System:

(1) Utilizing an imported proportional control system, the pressing speed can be automatically adjusted continuously and at multiple points based on the slurry’s dewatering performance and the characteristics of the pressed product, thereby enhancing the dynamic response during pressure transitions and ensuring both stable pressing speed and uniformity of pressing pressure.

(2) Utilizes a combination of high- and low-pressure oil pumps for oil supply, ensuring rational allocation of oil sources based on the pressing process, thereby minimizing system heat generation and eliminating the adverse effects of excess oil supply.

(3) The use of a plate-type integrated oil circuit system reduces leakage and makes adjustments and maintenance more convenient.

(4) Clamping force, ejector force (floating pressure in the lower cylinder), injection force, and mold-release protection force are all continuously adjustable.

(5) Features both standard demolding and protective demolding functions.

(6) Install the mold-pulling safety protection valve.

(7) Centralized oil return system equipped with a cooling device. Ensure the machine operates at normal temperatures.

3: Electric Control System:

(1) Utilizing internationally popular AI artificial intelligence control technology.

(2) Utilizes a PLC programmable logic controller for centralized control

(3) Utilize a human-machine interface touch screen to set and adjust various process operations and parameters—including mold clamping pressure, holding pressure, pressing speed, mold closing delay, material injection delay, holding pressure delay, pressure release delay, demagnetization delay, demolding method, mold cavity height, process curves, alarm display, press operation status display, fault descriptions, and operating instructions, among others.

(4) The device uses a displacement sensor for control, enabling automatic detection of the lower cylinder stroke. It also allows precise adjustment of the mold cavity and real-time monitoring of the pressing process directly from the human-machine interface.

(5) The PLC programmable controller, human-machine interface, and other key components are all original imported parts.

4. Magnetizing Coil Assembly: Stainless steel housing, water-cooled, capable of handling a high current of 500 amps with a total ampere-turn rating of 50,000.

5. Feed Mixing and Water Absorption System: Composed of a feeding cylinder, feed valve, mixing drum, vacuum pump, air storage tank, and more, the entire system is integrated into a single assembly. Both the hydraulically controlled feed valve and the composite feed cylinder feature the latest design innovations, ensuring high sealing performance and minimizing moisture content in the slurry. This not only reduces equipment maintenance needs but also enhances production efficiency.

6. Process Actions: The machine offers two process operation modes—manual and semi-automatic cycle. In manual mode, pressing the corresponding button initiates the desired process action, ideal for adjusting the machine or installing molds. In semi-automatic mode, pressing both hand buttons automatically triggers a complete process cycle. The semi-automatic protection cycle for demolding and pressing includes the following steps: lower cylinder ejects—slider rapidly descends—slider slows down—mold closes—automatic material injection—pressing at Speed 1—pressing at Speed 2—pressing at Speed 3—pressing at Speed 4—holding pressure (automatic material suction)—pressure relief (demagnetization)—lower cylinder retracts—upper cylinder returns—part removal and mold cleaning.

3. Introduction to the Electro-Hydraulic Proportional Control System for Magnetic Material Press Machines

(1) Oil Source Control: The oil source is equipped with a piston pump featuring a displacement of 10 ml/r and another pump with a displacement of

A 40 ml/r vane pump is configured to deliver low-to-high flow rates combined with high-to-low pressure outputs, driven simultaneously by the front and rear shafts of a single 7.5 kW, three-phase, four-pole motor. During different process stages, the output pressure is precisely controlled via a proportional overflow valve programmed to adapt to varying operational conditions.

(2) Upper Die Cylinder Control: By using a combination of a filling valve and proportional directional valves, the system can achieve various process speed requirements, including fast advance, slow advance, working advance, and fast return. A proportional overflow valve ensures smooth pressure relief in the rodless chamber, preventing pressure surges caused by on-off relief methods that could lead to cracking in the workpiece. Additionally, another proportional valve controls the backpressure in the lower cavity of the upper die cylinder, coordinating seamlessly with the fast advance, slow advance, and working advance stages to maintain balanced die movement and significantly enhance the quality of the machined parts.

(3) Lower die cylinder control: Controlled via a proportional directional valve program to achieve variable speeds, meeting the requirements for fast upward movement, rapid downward action, floating pressing, and die removal processes. A safety valve protects the lower die mold from being damaged by external forces.

(4) Core mold cylinder control is managed via another proportional directional valve program, enabling the adjustment of varying speeds to meet the requirements of fast upward movement, rapid downward descent, and efficient core mold removal. A safety valve protects the core mold from being damaged by unintended external forces.

The aforementioned proportional components, adjusted via a proportional ramp time, allow precise control over the transition periods for speed and pressure switching in each process step. This ensures smooth hydraulic cylinder movement, minimizes system pressure surges, and provides stable loading, all of which contribute to efficient and high-quality workpiece compression molding.

Previous entry:

Next:

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Automatic Hydraulic Press for Magnetic Materials

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.