Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

I. Core Application Areas

The High-Precision Hot Press Machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as a positioning accuracy of ±0.01 mm, temperature control precision within ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving multiple strategic emerging industries.

1. Consumer Electronics: The Ultimate Pursuit of Lightness, Thinness, and Precision

It is the core molding equipment for carbon fiber/glass fiber composite material phone back covers, VR/AR smart wearable devices (such as helmet frames and eyewear mounts), TWS earphone back covers, and tablet back covers.

- Case: The back cover of a smartphone (such as the iPhone 16 Pro Carbon Fiber Edition) must achieve "0.7mm thickness + flawless surface." A high-precision machine, equipped with a servo system offering positioning accuracy of ±0.01mm, prevents misalignment between fiberglass layers. Additionally, temperature control within ±1°C ensures uniform curing of the epoxy resin. As a result, the final product exhibits a thickness tolerance of less than 0.02mm and a surface roughness of Ra < 0.8μm—reaching mirror-like quality.

- Extension: The demand for "lightweight design + structural strength" in VR/AR devices (such as the Meta Quest 5 headset)—high-precision machinery enables the precise molding of "complex curved surfaces + thin-walled structures," ensuring both comfort and durability.

2. Aerospace: Precision Assurance in Extreme Environments

Suitable for hot pressing molding of high-performance components such as aero-engine blades, aircraft wing structural parts, and satellite brackets—applications that demand "high-temperature resistance, high-pressure capability, and exceptional strength," along with "zero tolerance for errors."

- Case: An aero-engine turbine blade (made from titanium alloy combined with carbon-fiber composite material) requires a process involving **multi-stage pressure application (pre-pressure—main pressure—holding pressure)** and **segmented heating (150°C → 300°C → 100°C)** to ensure perfectly aligned internal fiber structures (with an error margin of less than 0.05 mm), thereby enhancing its high-temperature resistance (above 1200°C) and improving fatigue performance (doubling its service life).

- Extension: The satellite bracket (made of carbon fiber) must achieve "lightweight design (40% weight reduction) + high rigidity (flexural modulus > 300 GPa)." Additionally, the high-precision machine's servo-based multi-axis synchronous control system—capable of ensuring mold-closing and ejection movements with an error margin of less than 0.01 mm—guarantees consistent bracket dimensions, thereby meeting the satellite launch requirement for "zero vibration."

3. Sports Equipment: The Perfect Balance of Performance and Personalization

For products such as carbon-fiber golf clubs, rackets, and sports shoe soles, we achieve "complex structures combined with precise performance control."

- Golf club heads: To optimize ball-striking performance, they incorporate an "internal center-of-gravity adjustment mechanism" (e.g., the TaylorMade Stealth 3 head). Advanced, high-precision machinery ensures precise multi-stage pressure settings—such as "100 MPa pre-pressure → 300 MPa main pressure → 50 MPa holding pressure"—which guarantee a seamless bond between the tungsten steel weight and the carbon fiber matrix. This results in a center-of-gravity error of less than 0.5 grams, enhancing shot stability by up to 30%.

- Racquet: Crafted using a "cushion internal pressure + external thermal pressing" process to create a hollow racquet frame (e.g., YONEX NF-800). The high-precision machine ensures **±0.01mm positioning accuracy**, guaranteeing uniform frame wall thickness (with an error margin of less than 0.1mm), while also expanding the sweet spot area by 15%—significantly enhancing the efficiency of power transfer during impact.

- Sneaker soles: Featuring "customized arch support + functional zoning" (e.g., Nike ZoomX Vaporfly 4%), this high-precision machine achieves differentiated curing of EVA/TPU materials through **segmented heating**—ranging from 120°C in the forefoot, to 150°C in the midsole, and up to 180°C at the heel—resulting in a final sole rebound rate exceeding 85% (10% higher than traditional manufacturing methods).

4. Automotive Manufacturing: Dual Assurance of Lightweight Design and Safety

Used for thermoforming carbon fiber body frames, doors, and interior components, meeting the demand for "30%+ weight reduction and 50%+ strength enhancement" (e.g., Tesla Cybertruck’s carbon fiber doors).

- Core Value: The high-precision press machine’s exceptional resistance to off-center loading—enabled by its four-column structure combined with a lower-cylinder drive—guarantees that large body components, such as 4-meter-long car doors, maintain parallelism errors below 0.05mm, preventing "stress concentration" during welding. Additionally, multi-stage pressure settings—such as "200 MPa pre-pressure → 500 MPa main pressure → 100 MPa holding pressure"—ensure carbon fiber interlayer density exceeds 98%, significantly boosting impact resistance by up to two times.

5. New Energy and Healthcare: The Foundation for High Reliability

- New Energy: The graphite crucibles used as negative electrode materials for lithium batteries—essential in the sintering process—must achieve "high density (>2.2 g/cm³) + low porosity (<1%)". A high-precision machine employs a vacuum hot-pressing process (with vacuum levels down to -0.095 MPa) to prevent bubble formation inside the crucibles, ultimately extending the product's lifespan by three times—from 500 cycles to 1,500 cycles.

- Medical: High-precision plastic components—such as surgical instrument housings—must meet the requirements of "burr-free + dimensional consistency." The high-precision machine features **±0.01mm positioning accuracy**, eliminating product burrs entirely (no need for post-processing grinding), and **±1°C temperature control** ensures optimal toughness in PC materials, delivering an impact strength exceeding 60 kJ/m².

II. Core Feature: Synergistic Enhancement of Precision and Efficiency

The "high" in a high-precision hot pressing machine essentially represents the combined result of **"servo system + intelligent control + structural optimization,"** with the following key features:

1. Servo System: The High-Precision "Brain"

- Closed-loop feedback control: Servo motors paired with encoders continuously monitor position, speed, and pressure in real time, enabling dynamic matching of "pressure-temperature-stroke" (response time < 10 ms). For instance, during carbon fiber prepreg molding, the pressure profile can be rapidly adjusted—increasing from 100 MPa to 300 MPa in just 0.5 seconds—to accommodate the "gelation-curing" characteristics of epoxy resins.

- Multi-axis synchronization: Controlled by a PLC, this system coordinates actions such as molding, ejection, and vacuum extraction with positioning accuracy of ±0.01 mm—five times higher than traditional hydraulic presses—effectively preventing the issue of products being "thicker on one side and thinner on the other."

- Energy saving and consumption reduction: Adopting an "on-demand energy supply" mode (operating at high power only during the pressurization/holding phases), resulting in a more than 60% reduction in no-load power consumption (compared to traditional hydraulic presses, where no-load energy consumption typically accounts for 30%-40%). Additionally, regenerative braking technology recovers energy during deceleration, achieving energy savings of 15%-25%, thus aligning with the "Dual Carbon" goals.

2. Temperature Control: A "Constant-Temperature Chamber" with ±1°C Precision

- Heating method: Employs an optimized design featuring electric heating plates combined with heating tubes (some models utilize far-infrared radiation). The heating process reaches 250°C from ambient temperature in under 20 minutes, with temperature fluctuations maintained within ±1°C—50% narrower than those of conventional machines.

- Segmented Temperature Control: Supports "multi-stage temperature ramp-up/ramp-down" settings (e.g., "100°C → 150°C → 200°C → 100°C"), tailored to the curing curves of various resins such as epoxy and phenolic. For instance, when molding phenolic resin, the process requires "gradual heating (10°C/min) → holding at a constant temperature (200°C for 30 minutes) → rapid cooling (20°C/min)," which can be precisely executed by the high-precision machine.

3. Pressure: "Precision Application" at ±0.1 MPa

- Pressure Control: Utilizing a servo hydraulic system (or servo electric cylinder) to achieve dual-mode control—either "constant pressure" or "constant stroke" (e.g., "300 MPa constant pressure + 20 mm constant stroke"). Pressure accuracy is maintained within ±0.1 MPa, which is three times higher than that of conventional machines.

- Multi-stage pressure control: Capable of storing 50–100 sets of process parameters (e.g., "Pre-press 50 MPa → Main press 300 MPa → Hold pressure 100 MPa"). When switching products, simply recall the corresponding program to automatically execute the sequence: "rapid upward movement—slow pressurization—pressure-holding curing—quick return."

4. Vacuum Function: Bubble-Free "Tight-Seal Assurance"

- Standard on select models: The vacuum hot-press machine achieves "vacuuming down to -0.095 MPa" (approaching absolute vacuum), preventing bubble formation during composite material molding—and boosting the yield rate from 85% to 98%.

- Automatic pressure replenishment/vacuum release: During the holding phase, if pressure drops (e.g., due to resin shrinkage), the system automatically replenishes the pressure (maintaining 300 MPa). After molding is complete, the system automatically releases the vacuum (restoring from -0.095 MPa back to atmospheric pressure in just 10 seconds), significantly boosting production efficiency.

5. Smartification: The "Connector" of Industry 4.0

- Ease of Operation: Features a touch-screen interface (user-friendly with support for switching between Chinese and English) that allows direct input of parameters such as "press-fitting force, temperature, and holding time." The system also displays real-time equipment status, e.g., "Current pressure: 250 MPa, temperature: 180°C, stroke: 15 mm."

- Remote Monitoring: Supports the MQTT protocol (for Industrial IoT), enabling users to remotely view equipment operation data—such as "Today's production: 1,000 units; defect rate: 0.5%"—via mobile phone or computer. It also provides early warnings for issues like "heating tube failure" or "pressure anomalies," with a response time of less than 1 minute.

6. Structure: The "Foundation" of Rigidity and Stability

Four-column structure: Features 45# steel columns that have undergone tempering treatment (diameter ≥100mm), offering exceptional resistance to eccentric loads (capable of withstanding eccentricity errors of less than 0.5mm under a 1000-ton pressure), ensuring "parallelism between the upper and lower molds" during the forming process (with a parallelism error of less than 0.05mm).

Bottom-cylinder drive: (for select models) features a compact design (taking up 20% less floor space compared to top-cylinder systems), offers convenient mold installation (with mold-change time under 30 minutes), and is ideal for "upward-pressure" processes such as flat vulcanization and composite material pressing.

Summary

The core value of a high-precision hot press forming machine lies in maximizing the integration of "material performance" and "forming accuracy"—achieved through precise servo system control, dynamic coordination of temperature and pressure, and reliable vacuum functionality, enabling "zero-error" transformation "from material to finished product." Its applications span multiple high-growth industries, including electronics, aerospace, sports equipment, automotive, and new energy, making it a critical piece of equipment for "precision manufacturing" under China's "Made in China 2025" initiative.

With the growing adoption of new materials like carbon fiber and glass fiber (global demand for carbon fiber is expanding at an annual rate exceeding 15%), high-precision hot press molding machines will continue to serve as the "cornerstone" of "high-end manufacturing," enabling more products to achieve the goals of being "lightweight, high-performance, and highly consistent."

Main performance and features of the equipment:

a. High temperature control accuracy of ±1°C;

b. The thermal plate temperature difference can be as low as ±2°C at best;

c. The hot plate can achieve a flatness accuracy as high as ±0.01 mm;

d. Multi-stage pressure control, with a hold time set separately for each pressure stage;

e. Pressure accuracy error is less than 1%;

o. Multiple venting function;

f. Multi-stage temperature control;

g. Scheduled heating function;

h. Menu-based save/restore functionality for product production data;

I. 1000-second ultra-long holding pressure function;

j. Heating methods: Optional electric heating tube or mold temperature controller heating;

k. Optional vacuum function;

Environmental equipment

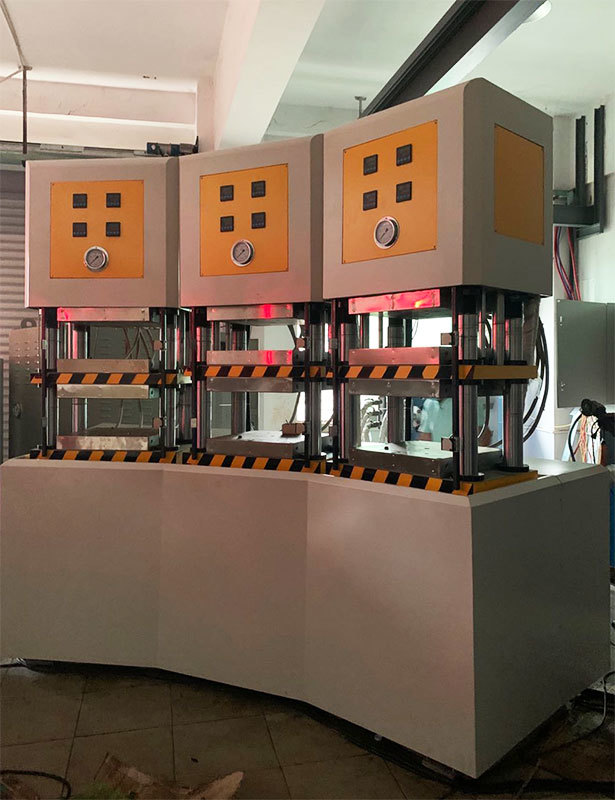

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Ultra-high-precision hot pressing machine

If you require custom-delivered products, Please contact us!

Category Belonging

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

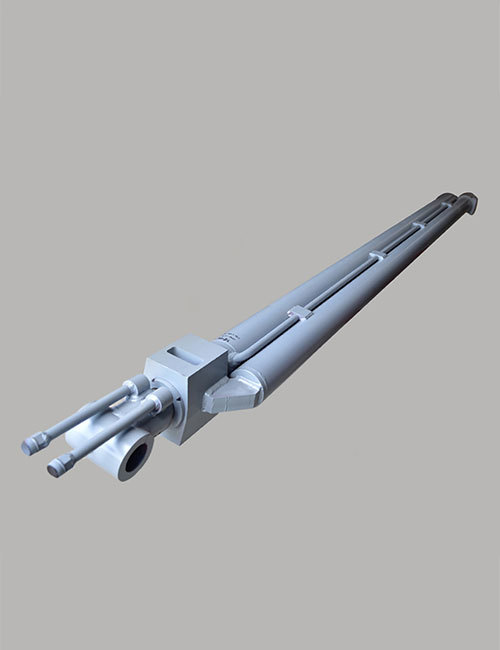

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

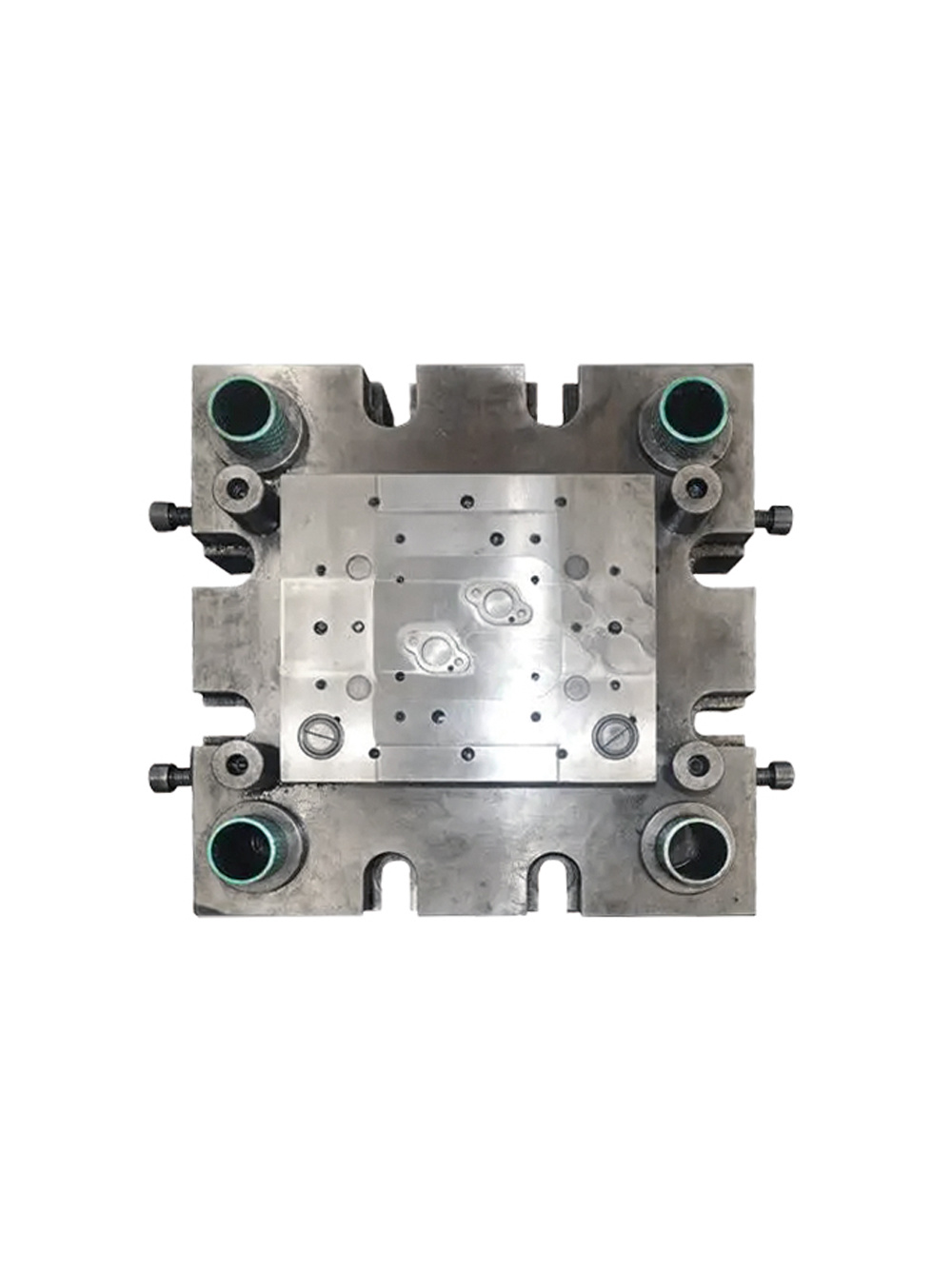

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.