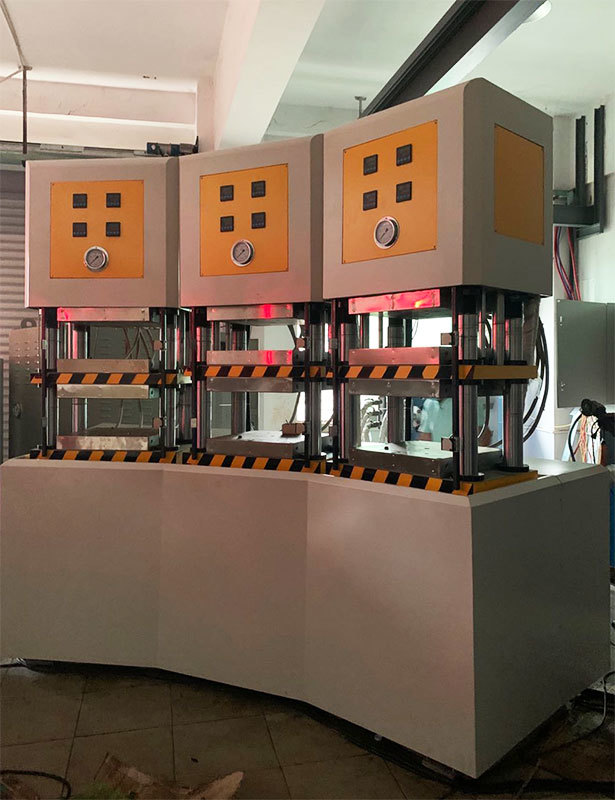

Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

I. Core Application Areas

The high-precision four-column, lower-cylinder hot press molding machine combines the "rigidity of its four-column structure," the "stability provided by lower-cylinder drive," and the "adaptability to hot pressing processes," making it widely used in precision molding and mass manufacturing—serving a variety of high-value industries.

1. Rubber and Thermoset Plastic Products

It is the core molding equipment for rubber products (such as bottle caps, seals, and tires) and thermoset plastic products (like phenolic resin parts). For example:

- Laboratory/Small-Scale Production: A below-100-ton, bottom-cylinder type flat vulcanizing press designed for pressing rubber samples or small-batch rubber products (such as sealing rings), enabling the vulcanization reaction (curing and shaping) of rubber through heat-and-pressure processing.

- Large-scale production: A few-hundred-ton, bottom-loading hot press machine designed for the thermoforming of large rubber products such as tire treads and rubber shock absorbers, ensuring product density and dimensional consistency.

2. Composite Materials and Protective Products

Suitable for hot pressing molding of composite materials such as carbon fiber, glass fiber, and PE, this equipment is critical for new energy, aerospace, and protective gear applications.

- In the new energy sector: a 315–800-ton lower-cylinder thermal compression molding machine, designed for manufacturing PE bulletproof helmets (thermal pressing enables interlayer bonding of composite materials, enhancing impact resistance) and graphite crucibles (specifically tailored for sintering lithium-battery anode materials, offering high density and exceptional shatter resistance).

- Aerospace: Rapid molding of carbon fiber prepregs (e.g., for wing skins, satellite brackets) using a downward-cylinder, upward-pressure process, ensuring precise fiber orientation and dimensional accuracy (tolerance ±0.05 mm), thereby meeting the demands for "lightweight design + high strength."

- Protective Equipment: An 800-ton bulletproof insert molding machine designed for hot stamping high-hardness steel plates or composite material inserts, capable of withstanding impacts exceeding 1500 MPa—ideal for applications such as military-grade bulletproof vest inserts.

3. Hot Press Molding of Metal Products

For products such as metal sheet metal, heads, and tank bodies, thermal pressing is used to reduce forming difficulties and enhance precision.

- Automotive Manufacturing: Large-scale, bottom-loading hot press forming machines (e.g., 500-ton or larger) are used to produce automotive body panels such as doors and hoods, as well as agricultural vehicle components. These machines utilize hot stamping at temperatures ranging from 200°C to 300°C to achieve precise plastic deformation of metal, ensuring superior roundness and dimensional accuracy—guaranteed within an error margin of ±0.1 mm.

- Minsheng Metal Products: Specializing in products such as boiler heads (including LPG tank bodies, stainless steel washbasins, and bathtubs), we utilize a bottom-cylinder hot pressing process to achieve metal stretching and bending—particularly for the hemispherical structure of the heads—ensuring superior sealing performance with zero leakage.

4. Eco-friendly and People's Livelihood Products

Focusing on the molding of green materials to meet the demands for "plastic reduction" and "environmental protection":

- Plant-fiber eco-friendly products—such as disposable fast-food containers, instant noodle bowls, plates, and more—are created by using a down-cylinder hot-press molding machine to shape plant fibers (like bamboo or rice husks) into durable forms. The process involves applying heat to bond the fibers together, resulting in biodegradable, pollution-free items.

- Sponges and polymer materials—such as sofa cushion foam and PC/PET plastic components like phone holders—are shaped and densified using heat-and-pressure techniques, enabling precise adjustments to their density and form (e.g., molding the sponge). This process ensures that everyday products meet both comfort and functionality requirements.

5. Electronics and Home Appliance Panels

For the molding of precision panels used in IMD/IML in-mold decoration and other applications, covering industries such as home appliances, electronics, and automotive.

- In the home appliance sector: Control and decorative panels for rice cookers, washing machines, and microwave ovens (such as PET/PC sheet thermoforming) are produced by heating the material with far-infrared heating elements, followed by instant molding under downward-cylinder pressure—ensuring both the panel’s glossy finish and precise dimensions (with an error margin of ±0.02mm).

- Electronics & Communications: Mobile phone back covers, computer keyboards, and landline phone panels (such as mobile phone lenses made using IML technology) can be produced in multiple specifications simply by changing the molds—for example, back covers tailored to different phone models. We also support high-volume production, with an hourly capacity of 50 to 100 units.

II. Core Features (The Combined Advantages of the Under-Cylinder and Four-Column Structures)

1. Four-column under-cylinder structure: high rigidity, high precision

- Structural Design: The machine features a three-beam, four-column structure (with one fixed crossbeam at the top and one at the bottom, supported by four vertical columns in the middle). It employs a lower-cylinder drive system—where the hydraulic cylinder is positioned at the base of the equipment—to push the moving worktable upward, applying pressure. This robust design offers 20%–30% higher rigidity compared to single-column models, making it exceptionally resistant to eccentric loading (ideal for high-tonnage applications). Additionally, the parallelism accuracy between the upper and lower working surfaces can be maintained within 0.08 mm—or even tighter at 0.05 mm or less for premium models—while ensuring smooth, vibration-free slider movement. This design effectively prevents mold damage or workpiece deformation caused by uneven loading.

- Spatial advantage: The lower-cylinder design ensures a compact equipment structure (occupying 15%-20% less floor space compared to the upper-cylinder type), making it easy to move or rearrange within the workshop. It also allows for convenient mold installation and replacement, reducing mold-change time by 20%-30%. This design is particularly suited for processes that require upward pressure, such as flat plate vulcanization and composite material compression molding.

2. High-precision hot-press control: Precise matching of temperature and pressure

- Temperature Control: Utilizes heating elements or hot plates (some models feature far-infrared radiation) for rapid temperature rise—reaching up to 280°C within just 30 minutes. Thanks to the advanced PID intelligent temperature controller, the system allows precise adjustment from ambient to 300°C, with a temperature accuracy of **±2–5°C** (for high-end models, this precision is as tight as ±1°C). For instance, during IMD/IML panel molding, it’s crucial to precisely control the heating temperature of the sheet material (e.g., PET or PVC—at around 180°C)—ensuring the material softens sufficiently to allow smooth shaping without any wrinkles or distortions.

- Pressure Control: Utilizes a cartridge valve-integrated hydraulic system (or servo-electric cylinder) to deliver stable pressure output with minimal impact. It supports two operational modes—constant pressure and fixed stroke—for processes such as the "pre-pressure-main pressure-hold pressure" cycle for composite materials, or the "vulcanization-hold pressure-demolding" process for rubber products. Pressure ranges from 1 ton (for small electronic components) up to 1000 tons (for large metal parts), with an accuracy of **within ±0.1 MPa**. For instance, during the thermoforming of a 315-ton bulletproof helmet, maintaining a consistent pressure level—such as 250 MPa—is critical to ensure the helmet’s superior impact resistance, meeting the requirements of GB 11810-2022 standards.

3. Process Flexibility: Adaptable to Multiple Materials and Specifications

- Mold Compatibility: Supports rapid mold changes (e.g., in IMD/IML panel molding machines, allowing production of different mobile phone cover models after switching molds), and is compatible with a wide range of materials—including rubber, composites, metal, plant fibers, and more. For instance, a 100-ton bottom-plunger hot press machine can produce either rubber sealing rings (φ10mm) or plant-fiber fast-food containers (200mm × 150mm) simply by swapping its molds.

- Program and Process Settings: Equipped with a PLC programmable controller, the system can store 50 to 100 sets of process parameters, including mold numbers, temperature curves, pressure profiles, and holding-pressure durations. When switching products, operators simply recall the corresponding program to seamlessly execute multi-stage actions such as "rapid upward movement—slow pressurization—pressure-holding curing—quick return." For instance, during the molding of carbon fiber prepregs, the process requires setting up a sequence like "heating to 150°C → applying pressure at 300 MPa → holding pressure for 10 minutes → cooling down to 50°C," which the PLC will then automatically carry out.

4. Safety and Operational Convenience

- Safety Protection: Equipped with mechatronic safety devices (such as a support circuit for the lower cavity of the cylinder and an interlock circuit for the upper and lower cavities of the cylinder) to prevent the slide from accidentally dropping. Additionally, there’s a through-beam optical sensor system (covering the moving table area), which instantly stops the equipment when a person or object enters the hazardous zone (response time < 0.1 second). Dual-button operation ensures safe handling—when manually loading or unloading materials, both buttons must be pressed simultaneously to start the machine, effectively preventing accidental activation.

- Ease of Operation: The device features a user-friendly touch-screen interface (as mentioned in Document 8, which highlights "intuitive and straightforward operation"). Users can directly input parameters such as pressing force, pressing speed, insertion depth, and holding time, while the system provides real-time feedback on equipment status—like temperature, pressure, and stroke. For instance, when producing plant-fiber fast-food containers, operators simply enter the settings on the touch screen—such as "10 tons of pressure, 120°C temperature, and 30 seconds of holding"—and the machine automatically completes the molding process.

5. Durability and Ease of Maintenance

- Durability: Equipped with advanced cylinder sealing components, such as NOK seals, ensuring high reliability and extending service life—up to twice as long as standard seals. Features an automatic rail lubrication system that regularly applies oil, significantly reducing rail wear and boosting lifespan by 30%. Additionally, selected models incorporate servo electric cylinders, offering exceptional longevity—up to five times longer than conventional cylinders—along with outstanding repeatability accuracy of ±0.02mm.

- Maintenance convenience: The equipment features a simple design (four-column, lower-cylinder type), making it easy to replace wear-and-tear components such as seals and heating elements. Additionally, 24/7 comprehensive after-sales support—including the "lifetime maintenance" service mentioned in Document 9—ensures rapid repairs in case of equipment failure, minimizing downtime to less than 4 hours.

Summary

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding," boasting features such as the "rigidity of its four-column structure," the "stability provided by bottom-cylinder drive," and "precise control of both temperature and pressure." These attributes enable it to meet the dual demands of "mass production" and "high precision" across diverse industries—including rubber, composite materials, metals, and eco-friendly products. As sectors like new energy, environmental protection, and electronics continue to grow rapidly—driven, for instance, by rising demand for lithium-battery anode materials and the increasing adoption of plant-fiber-based fast-food containers—the device will remain a critical enabler of "precision manufacturing," delivering efficient, reliable, and environmentally friendly molding solutions to businesses.

Main performance and features of the equipment:

a. High temperature control accuracy of ±1°C;

b. The hot plate temperature difference can be as low as ±3°C at best;

c. The hot plate flatness accuracy can reach up to ±0.02 mm;

d. Multi-stage pressure control, with hold time set separately for each pressure stage;

n. Multiple venting function;

e. Multi-stage temperature control;

f. Scheduled heating function;

g. Menu-based save/restore functionality for product production data;

h. 1000-second ultra-long holding pressure function;

I. Heating methods: Optional electric heating tube heating or mold temperature controller heating;

j. Optional vacuum function;

Next:

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

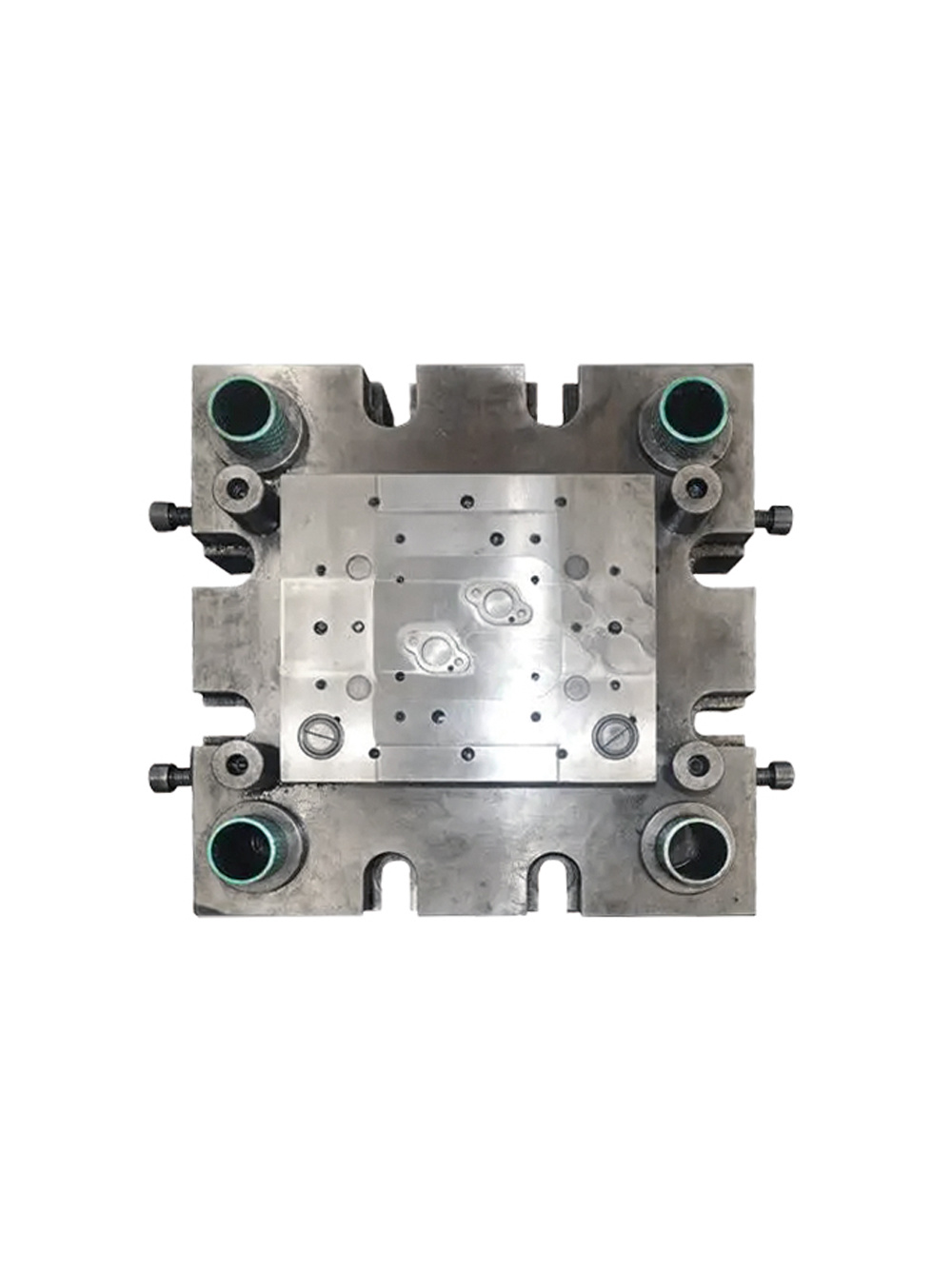

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

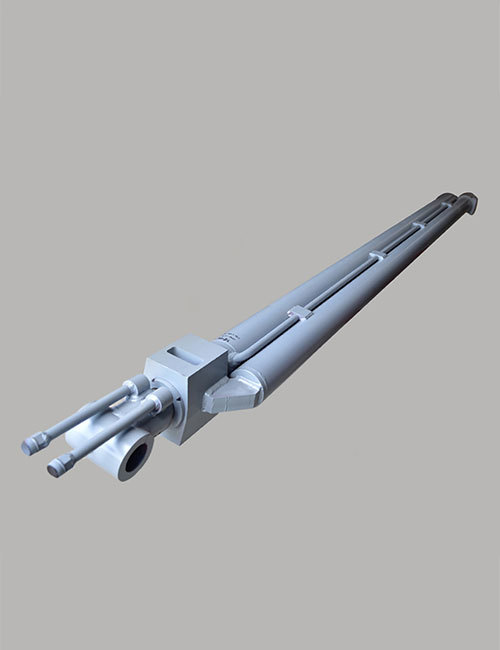

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.