Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

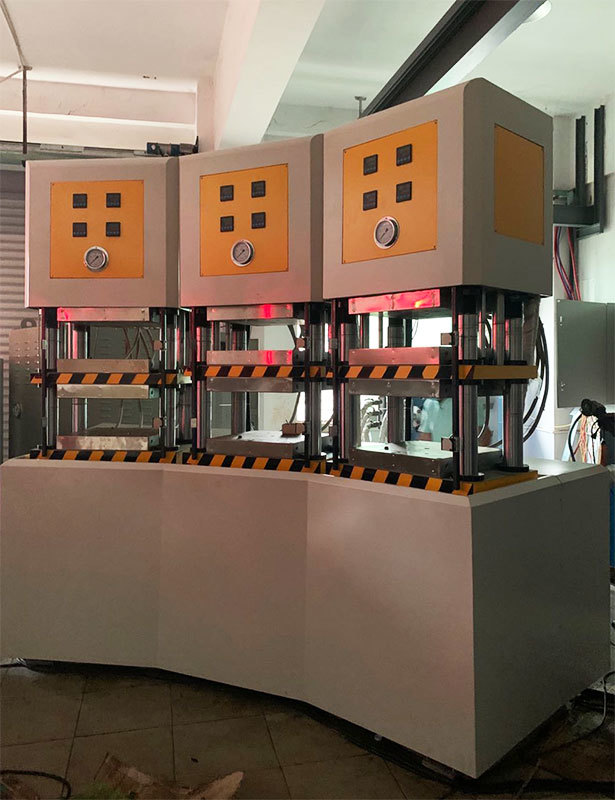

The high-temperature vacuum hot-pressing machine is a cutting-edge forming device integrating high-temperature heating, a high-vacuum environment, and high-pressure pressing, all coupled with precise control. By synergistically combining "high temperature + vacuum + pressure," it enables material densification, compounding, and the development of high-performance characteristics—making it widely used in advanced manufacturing fields such as ceramics, semiconductors, metal alloys, and composite materials. Its key features and applications are outlined below:

I. Core Features of the High-Temperature Vacuum Hot-Pressing Machine

1. High-Temperature Heating System: Precise temperature control, tailored to meet the needs of various materials

- Wide temperature range: Divided into two categories based on the application scenario—

- Medium-to-high temperatures (80–200°C): Used in consumer electronics and semiconductor packaging applications (such as carbon fiber molding for mobile phone back covers and ceramic substrate bonding), employing thermal oil or electric heating methods, with temperature uniformity maintained **within ±2°C** (References 2, 8, 10).

- Ultra-high temperatures (1500–1800°C): Used for ceramic sintering and heat treatment of metal alloys (e.g., aluminum nitride ceramic substrates, rare-earth alloys), employing resistance heating or induction heating to ensure materials reach sintering temperatures (Source 7).

- Multi-stage heating control: Supports segmented temperature ramp-up (e.g., "preheating - holding - curing"), with intelligent PID-based adjustment to maintain stable temperatures and prevent material defects caused by temperature fluctuations (References 3, 9, and 10).

2. High-vacuum environment: Eliminates impurities, ensuring material purity

- High vacuum level: Achieve a vacuum of 10⁻³ to 10⁻¹ Pa (for ceramic green sheet lamination) or **≤50 Pa** (for semiconductor electrostatic chucks), rapidly evacuating gases (such as air trapped in ceramic powders) and impurities from the materials. This prevents defects like oxidation and bubbles (References 4, 7, 8, 9).

- Vacuum efficiency: Some equipment can reach -70 mmHg (approximately 0.093 kPa) in as little as 10 seconds, significantly reducing process cycles (Sources 9 & 10).

3. Precise Parameter Control: Ultimate regulation for high-performance molding

- Pressure Control: Employs a servo closed-loop system, offering a pressure range of 20–500T (for consumer electronics) or 10–50 MPa (for ceramic sintering). Pressure fluctuations are maintained at **≤1%** within the 50–500T range, and multi-stage pressure settings are supported (e.g., "rapid pressurization – hold pressure – top-up pressure"), ensuring precise material compaction. (References 2, 3, 4, 8).

- Travel and Flatness: The upper and lower heating plates maintain a flatness of **±0.02 mm** and a parallelism of **±0.03 mm**. The guide posts are treated with high-frequency quenching, ensuring repeatable precision of **≤0.02 mm**, which guarantees uniform pressure distribution and prevents material warping (References 2, 3, 8, 9).

4. Automation and Intelligence: Enhancing Efficiency, Enabling Mass Production

- Automation Process: Supports fully automated loading and unloading (vibrating feeder + robotic arm feeding + material discharge), enabling a continuous "loading - compression molding - discharge" cycle while minimizing manual intervention (Document 5).

- Smart Control: Equipped with PLC program control, it supports manual, semi-automatic, and fully automatic modes. Key parameters—such as temperature, pressure, and vacuum level—are displayed in real time, and multiple process recipes can be saved. This system is ideal for producing diverse products in small batches (Refer to Materials 3, 5, 6, and 9).

5. Safety and Environmental Protection: Stable, reliable, and compliant with industrial standards

- Safety Protection: Equipped with multiple safety features such as overvoltage, overtemperature, and short-circuit protection. The heating system is enclosed in a stainless steel cover to prevent burns (Materials 1 & 3).

- Eco-friendly and energy-efficient: Vacuum technology reduces gas emissions, while servo-motor-driven oil pumps maintain pressure with zero energy consumption—resulting in over 30% energy savings compared to conventional equipment (Sources 1, 6, 9).

II. Main Application Areas of High-Temperature Vacuum Hot Pressing Machines

1. Ceramic Material Processing: A Core Application for High-Precision Molding

- Ceramic green tape lamination: Used in multilayer ceramic capacitors (MLCCs), this process stacks dozens of green tape layers with internal electrodes, followed by vacuum hot-pressing and co-firing to achieve high capacitance (≥100 μF) and miniaturization (≤0.4 mm × 0.2 mm) (Reference 8).

- Ceramic substrate sintering: Used for aluminum nitride (AlN) and alumina (Al₂O₃) substrates, this process involves high-temperature sintering at 1500–1800°C combined with high pressure ranging from 10 to 50 MPa, resulting in materials with exceptional thermal conductivity (AlN ≥ 180 W/m·K) and outstanding electrical insulation properties (≥ 10¹⁴ Ω·m). These substrates are ideal for heat dissipation in high-power electronic devices (Reference 7).

- Ceramic Electrostatic Chuck (ESC): Used in semiconductor lithography and etching machines, this device employs vacuum-assisted hot-pressing to form ceramic substrates, ensuring uniform temperature control during wafer processing—within ±1°C—and effectively preventing mechanical damage (refer to materials 4, 6, and 7).

2. Semiconductor Manufacturing: Key Equipment Supporting High-End Chips

- Ceramic substrate bonding: Used for power devices (such as IGBTs), this process involves thermally pressing copper foil onto the ceramic substrate to achieve a low void rate (<3%) and significantly enhance thermal performance (Reference 7).

- Semiconductor Packaging: Used in electrostatic chucks, this process leverages a high-temperature vacuum environment to bond carbon fiber with resin, enhancing the chuck's lightweight design—40% lighter than metal—and its superior corrosion resistance (referenced in Materials 6 and 7).

3. Metals and Alloys: Essential Tools for High-Temperature Heat Treatment

- Metal Powder Metallurgy: Used for rare-earth alloys and metal-ceramic composites, this process involves sintering in a high-temperature vacuum environment to inhibit grain growth, thereby enhancing material density (over 98%) and improving mechanical properties (Source 1).

- Superhard materials: Used in synthetic diamonds and PCD tools, these materials achieve a strong bond between diamond particles and the substrate under **high-temperature (>1000°C) + high-pressure (>5 GPa)** vacuum conditions (Source 1).

4. Composite Materials: The Preferred Choice for Molding Lightweight Products

- Carbon Fiber Reinforced Polymer (CFRP): Used in 2.5D back covers for smartphones and VR/AR helmets, this material is molded under high pressure—500 tons—at a temperature of 200°C after pre-impregnated layers have been carefully layered. This process results in lightweight components (60% lighter than metal) and exceptional strength (≥3000 MPa). (Sources 3 & 10)

- Carbon-based composite materials: Used in silicon carbide (SiC) and graphene applications, these materials achieve directional alignment via vacuum hot pressing, significantly enhancing thermal conductivity (≥500 W/m·K). They are ideal for thermal management in next-generation energy storage batteries (Sources 1 & 7).

5. New Energy and Consumer Electronics: Expanding Applications in Emerging Fields

- New energy materials—used in lithium-ion battery electrodes and fuel cell membranes—are processed under high-temperature, vacuum conditions to enhance their ionic conductivity and extend cycle life (Source 1).

- Consumer Electronics: Used for TWS earphone back covers and tablet rear casings, this solution leverages a quick die-change system (5–10 minutes) to accommodate production of multiple models, achieving high surface finish quality (Ra ≤ 0.8 μm). (Materials 3 & 10).

3. Summary

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material forming through the combination of "high temperature + vacuum + precise control." Its distinctive features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials. As the new energy and semiconductor industries continue to grow, this equipment will further evolve toward AI-driven process optimization (including machine learning-based parameter adjustments) and digital twin technology (enabling virtual debugging), thereby supporting the development of even more high-end products and accelerating the industry’s transition toward higher sophistication and intelligent innovation.

Main performance and features of the equipment:

a. High vacuum level, reaching up to 0.99 vacuum degree;

b. Maximum temperature: 3001°C–5001°C;

c. High temperature control accuracy of ±1°C;

d. The temperature difference across the hot plate can be as low as ±5°C at best;

e. The hot plate can achieve a flatness accuracy as high as ±0.03 mm;

f. Multi-stage pressure control, with each pressure stage having a separately set holding time;

g. Multiple venting function;

h. Multi-stage temperature control;

I. Scheduled Heating Function;

j. Menu-based save/restore functionality for product production data;

k. Three-stage pneumatic inflation function;

1. 1000-second ultra-long holding pressure function;

c. Heating methods: Optional electric heating tube heating or mold temperature controller heating;

d. Cooling method: Can be connected to a cooling tower or an ice water machine

Modular design: Customizable from 2 to 10 layers;

Previous entry:

Next:

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

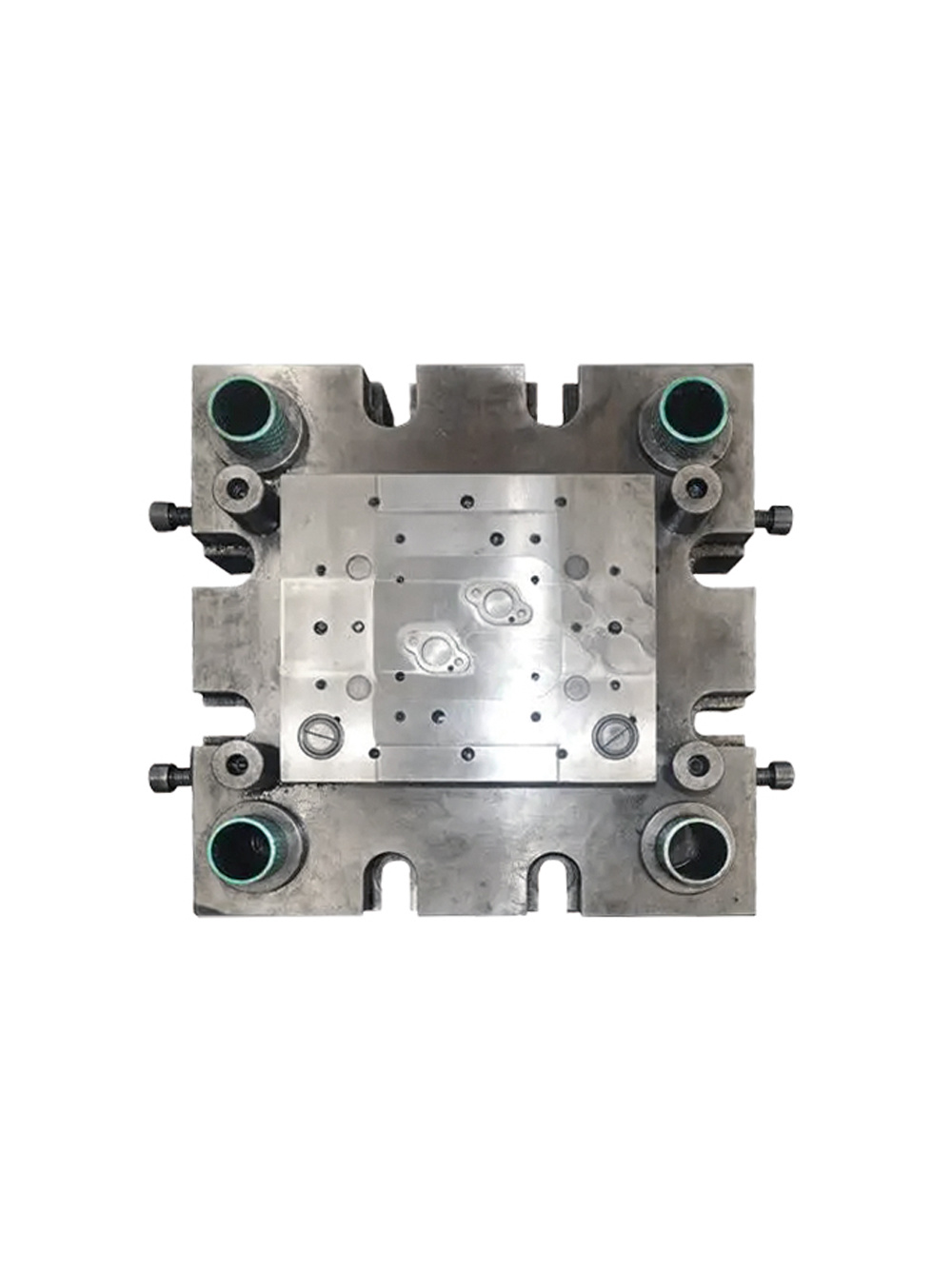

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

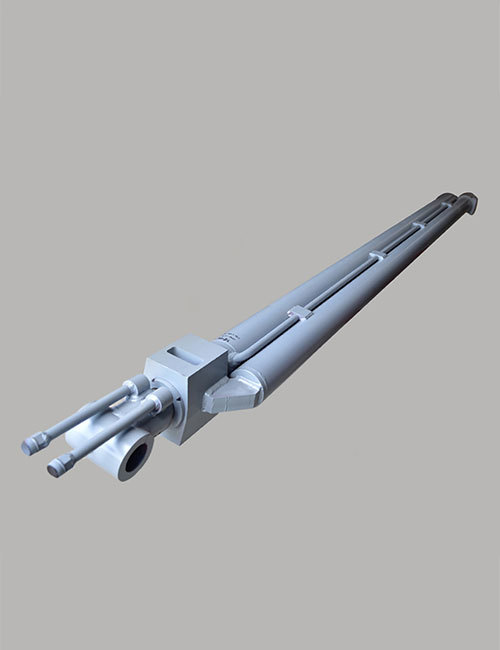

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.