Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

Multilayer hot pressing is a process that combines fibers—such as carbon or glass fibers—with a resin matrix under high temperature and pressure, resulting in composite materials boasting exceptional mechanical properties and lightweight characteristics. The basic principle of this technique involves layering multiple sheets of fiber material and resin matrix according to design specifications, then placing the assembly into a multi-layered hot-pressing hydraulic press. Heat is applied to soften and activate the resin, allowing it to flow freely. Under pressure, the resin thoroughly saturates the fibers while simultaneously expelling any trapped air bubbles. Finally, the material cures to form a composite product with a specific shape and tailored performance characteristics.

| Four-Column (Frame-Type) Multi-Stage Hot Press Hydraulic Molding Machine Parameter Sheet | |||||||

| Model Series | Maximum pressure (kN) | Heating plate dimensions (mm) | Layer spacing (mm) | Number of layers (N) | Maximum temperature (℃) | Heating method | Main application areas |

| BZ-RY-30T | 300 | 300 × 500 / 400 × 600 | 200 | 1-3 | 200 | Electric heating or mold temperature controller | Small electronic components, small medical devices |

| BZ-RY-50T | 500 | 400 × 500 / 600 × 800 | 200 | 1-5 | 300 | Electric heating or mold temperature controller | Phone back covers, tablet backplates, and small sports equipment |

| BZ-RY-100T | 1000 | 500 × 700 / 800 × 1000 | 250 | 1-5 | 300 | Electric heating or mold temperature controller | Laptop casings, bike racks, and mid-sized medical devices |

| BZ-RY-200T | 2000 | 800 × 1000 / 1000 × 1200 | 250 | 1-5 | 300 | Electric heating or mold temperature controller | Large communication equipment housings, rowing boats, and large medical devices |

| BZ-RY-300T | 3000 | 1000×1200/1300×1500 | 300 | 1-5 | 300 | Electric heating or mold temperature controller | Large antenna radomes, specialized sports equipment, and bulky medical devices |

I. Analysis of Multi-Layer Hot Press Molding Applications in the Electronics and Electrical Fields

1. Major Composite Materials Products in the Electronics and Electrical Fields

The electronics and electrical sectors are a key market for composite material applications, particularly in areas such as 5G communications, smart wearables, and consumer electronics, where demand is rapidly growing for lightweight, high-strength composites with excellent signal penetration capabilities.

Products in the electrical and electronics field that primarily utilize carbon fiber and glass fiber composites include:

5G communication equipment components:

- 5G phone back cover: Leveraging the lightweight, high-strength, and signal-penetrating advantages of carbon fiber composite materials.

- 5G base station antenna radomes: must offer excellent electromagnetic wave penetration and weather resistance.

- Communication equipment enclosure: Requires lightweight, high strength, and a certain level of electromagnetic shielding performance.

Smart wearable devices:

- VR/AR device casings: Pursuing lightweight design, high strength, and comfort.

- Smartwatch and wristband structural components: require lightweight, high-strength materials.

- Rigid support structure for wearable devices: Leveraging the high specific strength of carbon fiber.

Consumer electronics:

- Tablet backplate: Made from carbon fiber or glass fiber composite materials to achieve lightweight design and high strength.

- Laptop casing/base cover: Requires a material that is lightweight, high-strength, and offers excellent heat dissipation.

- TWS earphone back cover: Leveraging the lightweight, high-strength, and signal-penetrating properties of fiberglass panels.

Other electronic components:

- Circuit board substrate: Requires a composite material with excellent insulation properties and dimensional stability.

- Internal support structure for electronic devices: Leveraging the lightweight and high-strength properties of composite materials.

- E-cigarette body: Designed for lightweight construction, high strength, and sleek aesthetics.

2. Characteristics of Multi-layer Hot-Pressing Process for Electronic and Electrical Products

Composite material products in the electronics and electrical fields are typically thin-walled structures, demanding high precision in dimensions, superior surface quality, and excellent signal penetration. Their multi-layer hot-pressing molding process has the following key features:

Temperature control requirements:

- Lower curing temperature: Typically between 120–200°C to prevent damage to electronic components.

- Precise temperature control: Temperature fluctuations must be kept within a narrow range—typically ±1–2°C—to ensure consistent material performance.

- Rapid temperature control requirements: To enhance production efficiency, equipment often needs to have the ability to quickly heat up and cool down.

Pressure control requirements:

- Moderate molding pressure: Typically ranges from 1 to 10 MPa (equivalent to approximately 10 to 100 tons of force), depending on the material and product design.

- Uniform pressure distribution: Ensures even stress across all parts of the product, preventing deformation or uneven density.

- Multi-stage pressure control: A multi-step pressurization process may be required, involving low-pressure impregnation followed by high-pressure shaping.

Vacuum level requirements:

- High-vacuum environment: Typically, a vacuum level between 0.1 and 1 kPa (-0.1 to -0.095 MPa) is required to eliminate bubbles and enhance material density.

- Vacuum-assisted molding: Initiate vacuum during the pre-compression stage to reduce porosity and enhance product quality.

Characteristics of the molding cycle:

- Shorter molding cycles: Compared to industries like aerospace, the thermoforming cycle for electronic and electrical products is typically much shorter, usually ranging from 10 to 30 minutes.

- Suitable for mass production: The multi-layer hot-pressing molding process can meet the demands of large-scale manufacturing for electronic and electrical products.

II. Application Analysis of Multi-Layer Hot-Press Molding in the Sports Equipment Industry

1. Major Composite Material Products in the Sports Equipment Sector

The sports equipment industry was one of the earliest sectors to adopt carbon fiber and glass fiber composite materials, and their use has significantly enhanced the performance of sporting goods—such as lightweight design, strength, elasticity, and durability.

In the sports equipment sector, products that primarily utilize carbon fiber and glass fiber composite materials include:

Ball sports equipment:

- Tennis racket frame: Leveraging carbon fiber's high specific strength and excellent elastic properties.

- Badminton rackets: Designed for lightweight construction, high strength, and excellent elasticity.

- Golf clubs—comprising both the shaft and the clubhead—require high-modulus, high-strength composite materials.

- Table tennis racket: Requires appropriate elasticity and weight distribution.

Cycling sports equipment:

- Bicycle rack: Leveraging the lightweight, high-strength, and excellent shock-absorbing properties of carbon fiber composites.

- Bicycle wheelsets: Pursuing lightweight design, high strength, and aerodynamic performance.

- Cycling helmets require materials that are lightweight, high-strength, and offer excellent energy-absorbing properties.

Water sports equipment:

- Surfboard: Leveraging the lightweight and high-strength properties of carbon fiber and glass fiber composites.

- Rowing: Pursuing ultimate lightweight design and high strength to enhance speed.

- Kayaking: Requires materials that are lightweight, high-strength, and offer excellent waterproof performance.

Winter sports equipment:

- Snowboards require appropriate elasticity, lightweight design, and high strength.

- Ski poles: Leveraging the high specific strength of carbon fiber.

- Sledding: Pursuing lightweight design and high strength.

Other sports equipment:

- Hockey stick: Requires high strength and excellent flexibility.

- Archery equipment—including the bow and arrows—requires high-modulus, high-strength composite materials.

- Fitness equipment components: Leveraging the lightweight and high-strength properties of composite materials.

2. Features of the Multi-layer Hot-Press Molding Process for Sports Equipment Products

Sports equipment products are mostly structural components, placing high demands on the material's mechanical properties—such as strength, stiffness, and elasticity. Their multi-layer hot-pressing molding process has the following characteristics:

Temperature control requirements:

- Moderate curing temperature: Typically ranges from 150 to 250°C, depending on the material type and formulation.

- Precise temperature control: Temperature fluctuations must be kept within a narrow range—typically ±2–3°C—to ensure consistent material properties.

- A step-wise temperature ramp may be necessary: Depending on the material's curing characteristics, a step-wise heating curve might be required—such as starting at a low temperature and gradually increasing to a higher one.

Pressure control requirements:

- Higher molding pressure—typically ranging from 5 to 20 MPa (equivalent to about 50 to 200 tons of force)—is used to ensure the material achieves optimal density and mechanical performance.

- Even pressure distribution: For sports equipment with complex shapes, it’s essential to ensure that pressure is evenly spread, preventing localized defects.

- Multi-stage pressure control: A multi-stage pressurization process may be required, such as low-pressure impregnation followed by high-pressure shaping.

Vacuum level requirement:

- Higher vacuum requirements: Typically, a vacuum level of 0.1–1 kPa (-0.1 to -0.095 MPa) is needed to eliminate air bubbles and enhance material density.

- Vacuum-assisted curing: For high-performance sports equipment, curing may need to be performed under vacuum conditions to enhance material properties.

Characteristics of the molding cycle:

- Longer molding cycles: Compared to electronic and electrical products, the thermoforming cycle for sports equipment is typically longer, usually ranging from 30 to 90 minutes, depending on the material and product design.

- Post-curing may be required: Some high-performance composite materials may need additional post-curing treatment to achieve optimal performance.

III. Key Composite Materials Products in the Medical Field

The medical field places stringent demands on materials regarding biocompatibility, lightweight design, high strength, and precision manufacturing. As a result, carbon fiber and glass fiber composites—thanks to their exceptional performance characteristics—are increasingly being adopted in medical applications.

Medical applications primarily utilize products made from carbon fiber and glass fiber composites, including:

1. Medical equipment structural components:

- MRI equipment housing: Leveraging the lightweight and non-magnetic properties of carbon fiber composites.

- CT machine components: require materials that are lightweight, high-strength, and offer excellent radiation penetration.

- Medical robot components: Leveraging the high specific strength and lightweight properties of carbon fiber.

- Medical device moving parts: Striving for lightweight design and high strength to reduce energy consumption and enhance motion performance.

Medical implants and prosthetics:

- Orthopedic implants—such as artificial joints, bone screws, and bone plates—require materials that are highly biocompatible with human tissues.

- Dental implants: Require materials with excellent biocompatibility and mechanical properties.

- Prosthetic components: Leveraging the lightweight, high strength, and comfort offered by carbon fiber composites.

Medical assistive devices:

- Surgical table components: require lightweight, high-strength materials that are easy to clean.

- Medical bed structural components: Designed for lightweight construction and high strength to enhance mobility and safety.

- Rehabilitation equipment components: Leveraging the lightweight properties and excellent mechanical performance of composite materials.

Medical consumables and disposables:

- Medical splints: Leveraging the lightweight, high-strength, and X-ray penetrability of glass fiber composite materials.

- Medical packaging materials must possess excellent physical properties and biocompatibility.

- Structural components for single-use medical devices: striving for lightweight design combined with sufficient strength.

2. Characteristics of the Multi-layer Hot-Press Molding Process for Medical Products

Medical-grade composite materials for the healthcare sector have extremely high requirements for biocompatibility, dimensional accuracy, and surface quality. The multi-layer hot-press molding process used for these materials features the following characteristics:

Temperature control requirements:

- Moderate curing temperature: Typically between 150–250°C, ensuring material performance while preventing biocompatibility issues.

- Precise temperature control: Temperature fluctuations must be kept within a narrow range—typically ±1–2°C—to ensure consistent material properties and biocompatibility.

- Uniform temperature distribution: The entire working area must maintain a consistent temperature to prevent localized overheating or cooling, which could compromise product quality.

Pressure control requirements:

- Medium to very high molding pressure: Typically ranges from 5 to 20 MPa (equivalent to approximately 50 to 200 tons of force), depending on the material and product design.

- Precise pressure control: Pressure fluctuations must be kept within a narrow range to ensure consistent product quality.

- Multiple-stage pressure control may be required: Depending on the material's curing characteristics, a multi-stage pressurization process might be necessary.

Vacuum level requirement:

- High-vacuum environment: Typically, a vacuum level between 0.1 and 1 kPa (-0.1 to -0.095 MPa) is required to eliminate air bubbles, enhancing material density and biocompatibility.

- Inert gas protection may be required: For certain materials sensitive to oxidation, curing may need to be performed in an inert gas environment.

Characteristics of the molding cycle:

- Longer molding cycles: Compared to electronic and electrical products, the thermoforming cycle for medical devices is typically longer, usually ranging from 60 to 120 minutes, depending on the material and product specifications.

Strict curing control: Precise management of the curing process is essential to ensure the material's final performance and biocompatibility.

Summary

Through an analysis of the multi-layer thermoforming process requirements in three sectors—electrical and electronics, sports equipment, and medical devices—and a systematic summarization of the hydraulic press parameters for multi-layer thermoforming, we have arrived at the following key research findings:

Differentiated needs across application areas:

- In the electrical and electronics field: High precision in temperature control and vacuum levels are required, typically calling for lower curing temperatures (120–200°C) and enhanced temperature control accuracy (±1–2°C).

- In the field of sports equipment: These applications place high demands on both pressure and material mechanical properties, typically requiring significant molding pressures (5–20 MPa, equivalent to roughly 50–200 tons of force) and moderate temperatures (150–250°C).

- Medical field: Highly demanding in terms of biocompatibility, dimensional accuracy, and surface quality, this area typically requires precise temperature control (±1–2°C) and elevated vacuum levels (0.1–1 kPa).

Common parameters of multi-layer hot-pressing hydraulic presses:

- Temperature control accuracy: Most applications across the three fields require temperature control precision within a range of ±1–2°C to ensure consistent product quality.

- Pressure uniformity: Both require the workbench's flatness and parallelism to be tightly controlled at a high level (typically ≤0.05 mm and ≤±0.03 mm, respectively), ensuring even pressure distribution.

- Vacuum requirements: Most applications demand a vacuum level of 0.1–1 kPa (-0.1 to -0.095 MPa) to enhance material density and improve product quality.

Key factors in equipment selection:

- Product size and batch quantity are the primary factors determining the workbench dimensions and the number of mold layers.

- Material properties: Different materials have varying requirements for temperature, pressure, and curing time, directly influencing the selection of equipment parameters.

- Process requirements: Different molding processes—such as whether vacuum assistance is needed or if multi-stage pressure control is required—place varying demands on equipment configuration.

Applicability of the Universal Series Models:

- 30-ton model: Primarily suitable for small electronic components, small sports equipment parts, and compact medical products.

- 50-100-ton models: Ideal for producing medium-sized products, this is the most widely used model series.

- 200–300-ton models: Primarily suited for large-scale products and applications with high-pressure requirements.

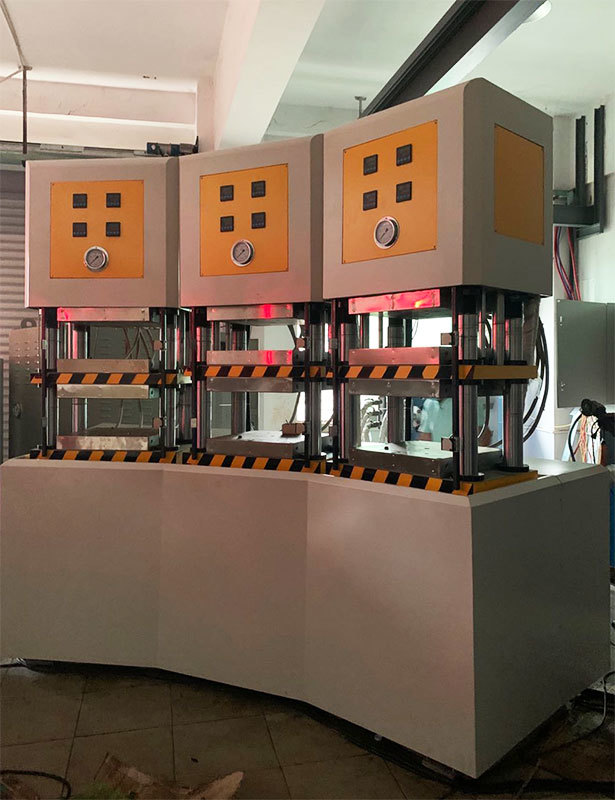

Performance and features of the multi-layer hot press machine:

a. High temperature control accuracy of ±2°C;

b. The temperature difference across the hot plate can be as low as ±5°C at best;

c. The hot plate flatness accuracy can reach up to ±0.03 mm;

d. Multi-stage pressure control, with each stage having a separately set holding pressure time;

e. Multiple venting function;

f. Multi-stage temperature control;

g. Scheduled heating function;

h. Menu-based save/restore functionality for product production data;

I. Three-stage pneumatic inflation function;

j. 1000-second ultra-long holding pressure function;

k. Heating methods: Optional electric heating tube heating or mold temperature controller heating;

1. Optional vacuum function;

m. Module Configuration: 1–10 layers customizable;

Previous entry:

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

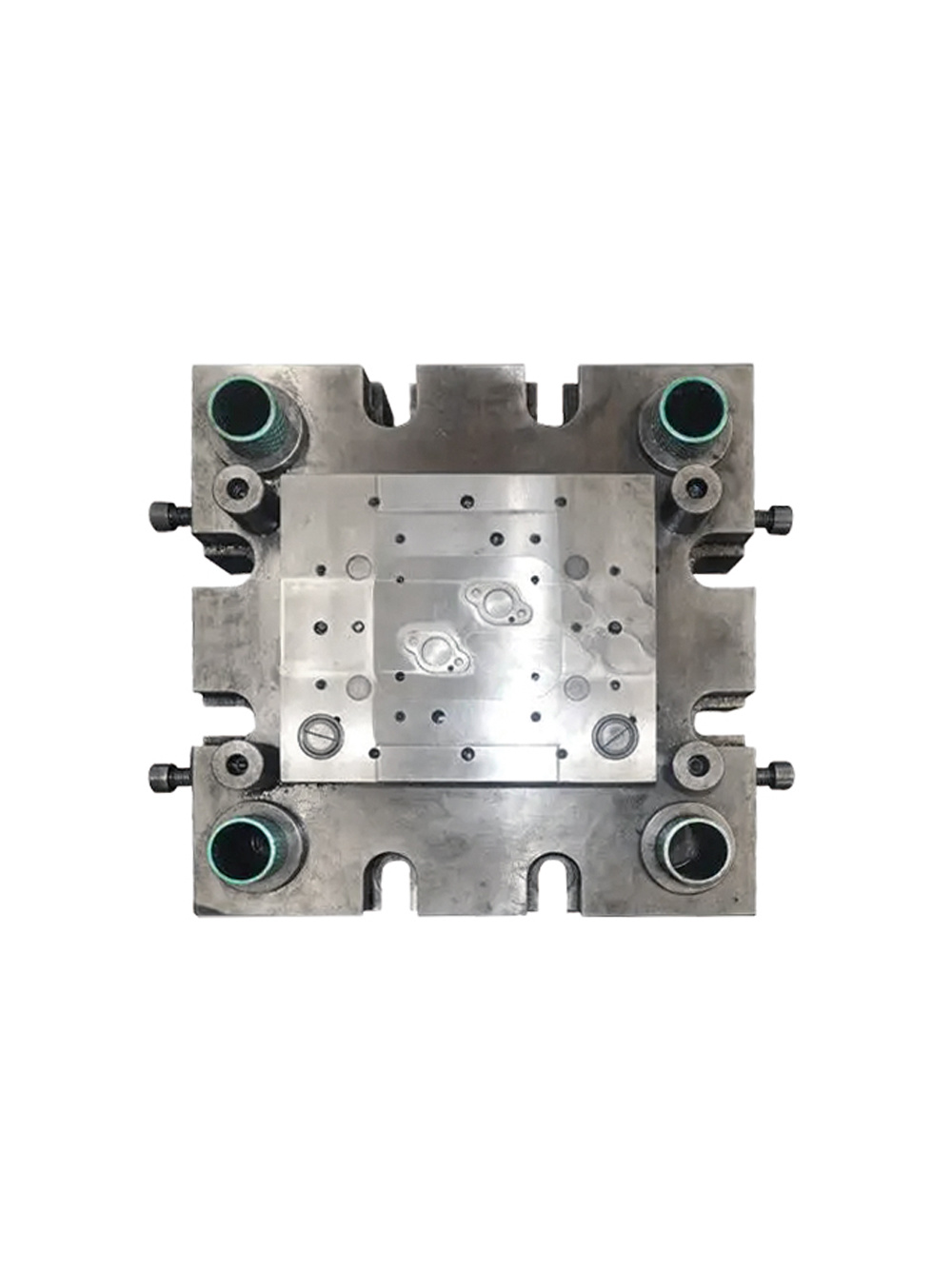

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

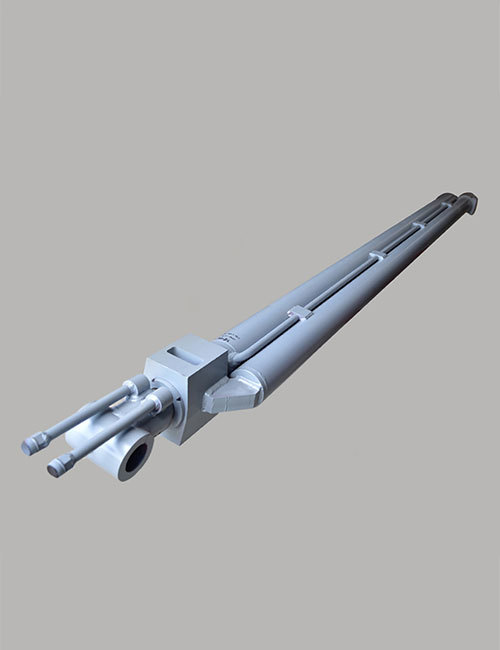

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.