Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

I. Core Application Areas

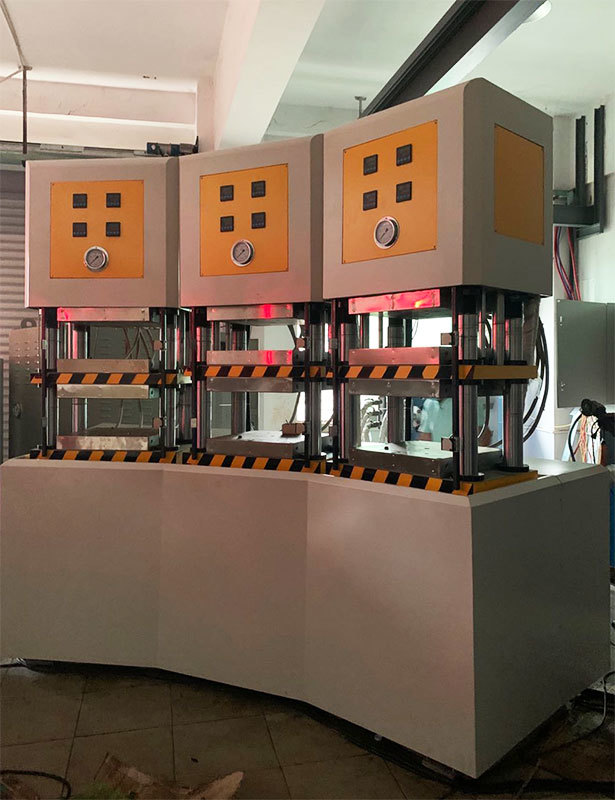

The high-precision four-column, upper-cylinder hot press molding machine combines "the stability of four-column guidance," "the precision of upper-cylinder drive," and "the versatility of the hot pressing process," making it widely used in precision molding and advanced manufacturing applications across multiple high-value industries.

1. Composite Materials and New Energy Components

Suitable for thermal pressing of materials such as carbon fiber prepregs, glass-fiber-reinforced plastics, and graphite crucibles—this is essential equipment for the new energy and aerospace industries.

- In the lithium-battery field: Used for manufacturing graphite crucibles (specifically designed for sintering lithium-battery anode materials), these crucibles achieve high density—thanks to ultra-high pressure ranging from 315 to 1000 tons—which ensures exceptional durability and resistance to cracking. They also support custom production in a variety of sizes, as different specifications can be easily produced simply by changing the mold.

- Aerospace: Manufacturing carbon-fiber laminates and sandwich structures (such as wing skins or satellite brackets) requires precise control over fiber orientation and dimensions—with tolerances of ±0.05 mm—to ensure components achieve both "lightweight design and exceptional strength" (tensile strength ≥ 500 MPa).

- Wind power industry: Thermal molding used for carbon-fiber wind turbine blade skins, meeting the demands for large dimensions (length > 10 meters) and high reliability (fatigue resistance).

2. Protective and Safety Products

For products with high protection requirements, we achieve "hot pressing + performance enhancement":

- Bulletproof equipment: Manufacturing PE bulletproof helmets (hot-pressed for guaranteed impact resistance) and 800-ton bulletproof plates (high-hardness steel sheets hot-stamped, capable of withstanding impacts exceeding 1500 MPa).

- Anti-riot equipment: such as riot shields (precision-molded from composite materials), which achieve interlayer bonding through thermal pressing, enhancing their protective capabilities.

3. Precision Electronics and Consumer Products

Focusing on small-sized, high-precision electronic components and consumer products, this is a key forming device for consumer electronics.

- Electronic components: Manufacturing film switches and membrane panels (such as key caps for mobile phones/remote controls) requires precise control of the embossing depth (with an error margin of ±0.01 mm) to ensure optimal tactile feedback and long-lasting durability of the buttons.

- Plastic/Silicone Products: Used for silicone keypads for mobile phones (heat-pressed molding ensures dimensional consistency), and PC/PET film housings (heat pressing enables plastic deformation). We support mass production, with an hourly capacity of 30–50 units.

4. Metal Hot Stamping and Sheet Metal Forming

By integrating thermoplastic principles, we can reduce the difficulty of metal forming and enhance product precision.

- Automotive Manufacturing: Produces automotive body panels (such as doors and hoods) by employing hot stamping—where metal is plastically deformed at temperatures between 200°C and 300°C—to ensure precise roundness and dimensional accuracy (with tolerances of ±0.1 mm).

- Household items: such as stainless steel washbasins (stretch-formed) and boiler heads (hot-pressed to ensure sealing performance), ideal for mass production (with an hourly capacity of 20–30 units).

5. Eco-friendly and Everyday Consumer Products

Addressing eco-friendly materials and everyday needs, we achieve "hot pressing + green manufacturing":

- Eco-friendly packaging: Producing plant-fiber disposable food containers and instant noodle bowls (heat-pressed and biodegradable) to meet the demand for "plastic reduction."

- Rubber products—such as seals and tires (formed via rubber vulcanization)—undergo thermal pressing to cure the resin at temperatures between 150°C and 200°C, ensuring superior sealing performance with a leakage rate of less than 0.1%.

II. Core Features (The Combined Advantage of High Precision and Versatility)

1. Four-column guide structure: High rigidity and resistance to eccentric loads

Featuring a design with four upright columns and precision guide bushings (some models use a five-beam, four-column configuration), the overall rigidity is 20%-30% higher than that of single-column systems, offering superior resistance to eccentric loads—making it ideal for high-tonnage pressing applications. The parallelism accuracy of the upper and lower working surfaces can be maintained within 0.08mm (for high-end models, this tolerance is even tighter—below 0.05mm)—while ensuring smooth slider movement without any wobbling. This design effectively prevents mold damage or workpiece deformation caused by uneven loading.

2. Top-cylinder drive: Precise pressurization and convenient operation

- Structural advantages: The hydraulic cylinder is positioned at the top of the equipment, driving the slider downward to apply pressure. This results in a compact design (requiring minimal floor space and easy mobility), as well as convenient mold installation and replacement—reducing mold-change time by 30%.

- Precision Assurance: The upper-cylinder design ensures more direct pressure transmission, making it ideal for downward-pressure processes such as hot embossing and metal stretching. It guarantees that each downward press reaches a consistent position (repeatability accuracy of ±0.01 mm), perfectly meeting the demands for "small dimensions and high consistency"—for instance, in applications like smartphone button embossing.

3. High-Precision Hot-Press Control: Precise Matching of Temperature and Pressure

- Temperature Control: Utilizes heating elements or hot plates (with some models featuring a heated chamber) for rapid temperature rise—reaching up to 280°C within 30 minutes. Temperature is precisely regulated from room temperature up to 300°C via a smart PID controller, with temperature accuracy maintained at **±2–5°C** (for high-end models, ±1°C), ensuring optimal curing or shaping of materials such as resins and rubber.

- Pressure Control: Employs a cartridge valve-integrated hydraulic system (or CNC PLC hydraulic drive), ensuring stable pressure output with minimal impact. It supports two operational modes—constant-pressure and constant-stroke processes—such as the "pre-pressure, main pressure, and holding pressure" sequence used for composite materials. The pressure range spans from 1 ton (for small electronic components) to 1000 tons (for large metal parts), with an accuracy of **±0.1 MPa or better**.

4. Process Flexibility: Multi-Material and Multi-Specification Compatibility

- Program storage: Supports storing over 100 sets of process parameters (such as mold numbers, temperature curves, and pressure profiles). When switching products, simply recall the corresponding program to significantly reduce mold-change time.

- Multi-stage process: Allows setting multiple action sequences such as "rapid descent - slow pressurization - pressure-holding curing - rapid return," tailored to meet the molding requirements of various materials (e.g., the "heating → pressurization → curing → cooling" process for carbon fiber prepregs, or the "vulcanization → pressure-holding → demolding" sequence for rubber).

5. Safety and Energy Efficiency: Balancing Performance with Protection

- Safety Design: Equipped with through-beam photoelectric sensors (covering the opening area), mechatronic interlock circuits (interlocking the upper and lower chambers of the cylinder), an emergency stop button, and safety hand guards to ensure operator safety (preventing crushing injuries caused by misoperation).

- Energy Efficiency: Featuring a servo closed-loop control system with zero overflow losses, this solution achieves energy savings of 30% to 50%. It also operates quietly—producing noise levels below 70 dB—making it ideal for continuous, high-volume production processes, such as the 24-hour uninterrupted operation required in crucible manufacturing.

Summary

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," boasting features such as "stable four-column guidance," "precise upper-cylinder actuation," and "accurate temperature and pressure control." These capabilities enable it to meet the demanding requirements of high-end products—including composite materials, electronic components, and metal goods—that demand "small dimensions, high precision, and large-scale production."

As industries like new energy, aerospace, and consumer electronics continue to grow rapidly—driven, for instance, by an annual growth rate exceeding 15% in automotive composite material usage—the device will play a vital role in supporting the industry’s ongoing shift toward "lightweighting" and "high-end sophistication," firmly establishing itself as a critical enabler of "precision manufacturing."

Main performance and features of the equipment:

a. High temperature control accuracy of ±1°C;

b. The hot plate temperature difference can be as low as ±3°C at best;

c. The hot plate can achieve a flatness accuracy as high as ±0.02 mm;

d. Multi-stage pressure control, with each stage having a separately set holding pressure time;

e. Multi-stage temperature control;

f. Scheduled heating function;

g. Menu-based save/restore functionality for product production data;

h. 1000-second ultra-long holding pressure function;

I. Heating methods: Optional electric heating tube heating or mold temperature machine heating;

j. Optional vacuum function;

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

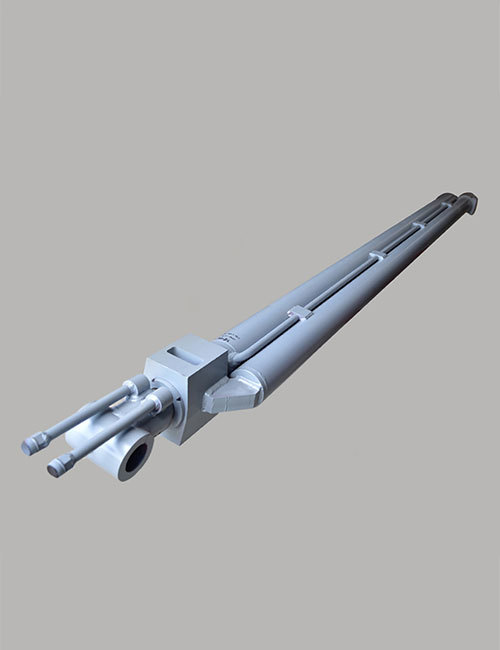

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

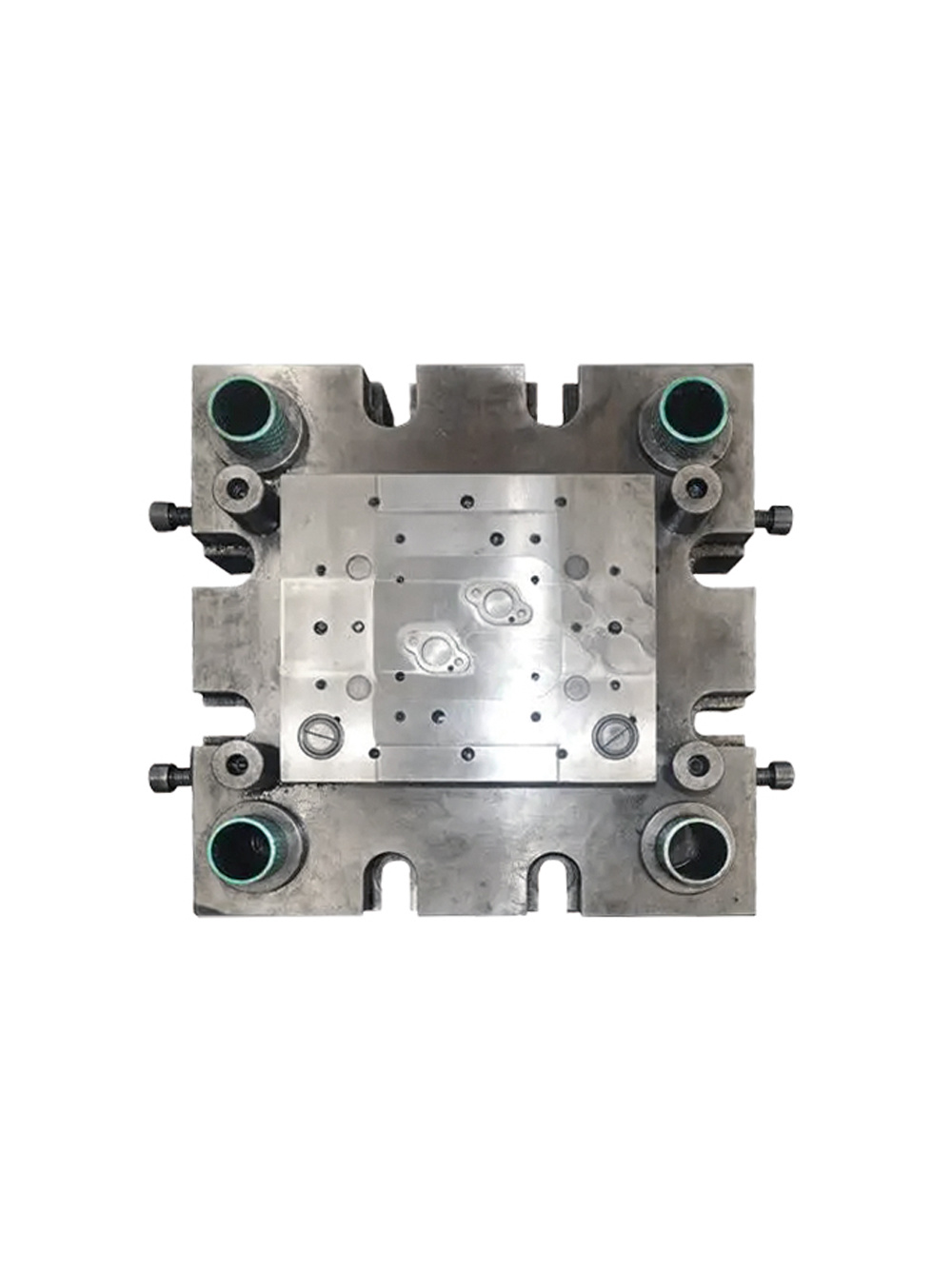

Precision Stamping Die

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.