Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Product Description

I. Core Application Scenario: Focusing on the "Essential Precision Needs" of High-End Manufacturing

The high-precision vacuum hot-pressing machine leverages the synergistic advantages of "high vacuum + high precision + hot pressing," serving multiple strategic emerging industries—including electronics semiconductors, new materials, aerospace, automotive, and medical—while addressing the industry's critical demands for "high density, minimal defects, and exceptional consistency," which traditional processes have struggled to meet.

1. Electronic Semiconductors: Ensuring "Zero Defects" in Packaging and Devices

- Multilayer Ceramic Capacitors (MLCCs): These components require dozens of layers of ceramic green sheets to be alternately stacked with internal electrodes. High-precision vacuum hot pressing ensures bubble-free interlayer bonding (with a void rate below 1%) and exceptional flatness—within ±0.02 mm—guaranteeing that, after co-firing, the capacitance (e.g., reaching 10 μF for the 0201 MLCC size) and miniaturization (measuring just 0.2 mm × 0.1 mm) are achieved. As a result, MLCCs have become essential components in electronic devices such as smartphones and computers.

- Ceramic substrates (Al₂O₃/AlN): DBC (Direct Bonded Copper) substrates used for power devices such as IGBTs, requiring a high-strength bond between copper foil and ceramic. Vacuum hot pressing ensures low void rates (<3%), boosts thermal conductivity by up to 20% (e.g., AlN-based substrates achieve a thermal conductivity of 200 W/m·K), and maintains precise temperature uniformity within ±1°C, preventing device overheating and failure.

- Electrostatic Chuck (ESC) and Heating Plate: Core components in semiconductor lithography equipment, requiring high density (>98%) and temperature uniformity within ±0.5°C. High-precision vacuum thermal pressing effectively addresses the challenge of uniformity for large-size components exceeding 12 inches, ensuring stable temperatures during wafer processing—critical for advanced processes like TSMC’s 5nm technology, where these tools serve as essential production equipment.

2. New Materials: The "Building Block" for High-Performance Composites

- Carbon fiber/glass fiber products: Such as carbon fiber phone back covers (e.g., the iPhone 16 Pro Carbon Fiber Edition) and glass fiber tablet casings, require thin walls (0.7mm) combined with high rigidity (flexural modulus > 300 GPa). Vacuum-assisted thermal pressing ensures precise fiber alignment (with tolerances below 0.05 mm), uniform resin curing (at a temperature controlled within ±1°C), and surface roughness Ra < 0.8 μm (achieving mirror-like quality). Additionally, these lightweight solutions reduce weight by 30%—about 50 grams lighter than traditional metal back covers.

- Graphene Composite Materials: High-thermal-conductivity Thermal Interface Materials (TIMs) require aligned graphene fillers. Vacuum hot pressing enhances the thermal conductivity in the vertical direction to over 50 W/m·K—twice higher than conventional TIMs—making them ideal for cooling solutions in 5G base stations and servers, such as the core heat-dissipating components used in Huawei’s 5G base stations.

- Ceramic matrix composites, such as SiC fiber-reinforced ceramics, require high densification (>95%) and must be free from oxidation. Vacuum hot pressing can achieve strong bonding between fibers and the matrix at temperatures as high as 1500°C, making these materials ideal for aerospace engine blades designed to withstand extreme temperatures exceeding 1200°C.

3. Aerospace: "Structural Safety" in Extreme Environments

- Carbon fiber structural components—such as aircraft wing frames and satellite supports—require lightweight designs (achieving a 40% weight reduction) combined with exceptional strength (doubling impact resistance). High-precision vacuum hot pressing ensures consistent structural dimensions (with tolerances below 0.03mm) and interlayer density exceeding 98%, perfectly meeting the zero-vibration demands of space environments—critical for applications like SpaceX’s Starlink satellite supports.

- Metal-ceramic components—such as titanium alloy-ceramic composite engine parts—require oxidation-free conditions (vacuum level of 10⁻³ Pa) and uniform pressure (within ±1%). Vacuum hot pressing helps prevent metal oxidation, significantly enhancing the components' high-temperature resistance (up to 1200°C) and fatigue performance (resulting in a lifespan that’s twice as long).

4. Automotive Manufacturing: A "Dual Boost" of Lightweight Design and Safety

- Carbon fiber body components—such as the carbon-fiber doors on Tesla’s Cybertruck—require a weight reduction of more than 30% and a strength increase of up to 50%. High-precision vacuum hot pressing enables the production of large-scale parts (up to 4 meters long) with parallelism tolerances as tight as ±0.05 mm, preventing stress concentrations during welding and significantly enhancing impact resistance—for instance, reducing door deformation by 40% in crash tests.

- New energy battery components, such as lithium-battery anode graphite crucibles, require high density (>2.2 g/cm³) and low porosity (<1%). Vacuum hot pressing helps eliminate internal air bubbles in the crucible, significantly extending its lifespan—from 500 cycles up to 1,500 cycles—while also reducing battery production costs.

5. Healthcare and New Energy: "Precision Fabrication" of High-Reliability Products

- Medical-grade precision plastic components: Such as surgical instrument housings (e.g., laparoscopic instruments) must be burr-free and dimensionally consistent (with tolerances below 0.02mm). High-precision vacuum thermoforming ensures seamless edges—eliminating the need for post-processing grinding—and maintains the toughness of PC materials (impact strength > 60 kJ/m²), fully meeting the stringent sterilization requirements for medical devices.

- New energy thermal interface materials (TIMs)—such as graphene-silicone grease composites—require aligned filler particles. Vacuum hot pressing can significantly enhance thermal conductivity in the vertical direction (>40 W/m·K), ensuring uniform temperature distribution within the battery module (within ±2°C) and ultimately extending battery life—for example, boosting the lifespan of CATL’s ternary lithium batteries by up to 15%.

II. Key Features: The Synergistic Advantage of Precision and Performance

The "high" precision of the high-precision vacuum hot-pressing machine is fundamentally the result of a combination of "precise parameter control + vacuum environment + intelligent operation," with the following key features:

1. High-precision parameter control: Ultimate process stability

- Temperature Control: Employs a multi-stage heating system—either electric heating or far-infrared technology—with temperature accuracy within ±0.5°C (some models achieve up to ±0.1°C), ensuring uniform heating of materials (e.g., consistent heating of ceramic raw sheets within ±2°C).

- Pressure Control: The servo closed-loop system enables precise pressure adjustment (pressure range of 20–500T, with an accuracy of ±1%), while segmented pressurization (pre-pressure—main pressure—hold pressure) ensures optimal material density—for instance, achieving carbon fiber density exceeding 98%.

- Vacuum Control: Achieves high vacuum levels as low as 10⁻³ Pa, with rapid evacuation capabilities—reaching 2.6 kPa within just 1 minute—effectively removing gases from materials (such as air trapped in ceramic powders) to prevent bubble formation.

2. Advantages of a vacuum environment: No oxidation and high density

- Oxidation-free protection: A vacuum environment prevents materials from oxidizing at high temperatures (e.g., active metal titanium electrodes), preserving their original properties—such as maintaining the thermal conductivity of AlN substrates without degradation.

Eliminating bubbles and impurities: Under vacuum conditions, gases within the material are rapidly removed, minimizing voids in the final product (e.g., reducing ceramic substrate porosity to below 3%) and enhancing product strength (e.g., increasing impact resistance of carbon fiber components by up to 30%).

3. Efficiency and Consistency: The Core Guarantee of Mass Production

- Short cycle time: Compared to traditional sintering processes, the hot-pressing cycle is shortened by more than 50% (e.g., the hot-pressing cycle for MLCCs is reduced from 2 hours to just 40 minutes), significantly boosting production efficiency.

- High Consistency: Powered by PLC program control, this system allows multi-segment parameters (pressure, temperature, and time) to be stored and easily recalled—enabling the storage of over 50 process programs. It delivers exceptional batch-to-batch stability (CPK > 1.67), reducing defect rates to below 0.5% (compared to approximately 3% with traditional methods).

4. Intelligence and Flexibility: Adapting to Diverse Needs

- Intelligent Operation: The touchscreen interface supports real-time parameter monitoring (e.g., current pressure, temperature, and vacuum level), while the remote monitoring feature—powered by the MQTT protocol—enables early warnings for equipment status issues such as heating tube failures or abnormal pressure conditions. Response time is less than 1 minute.

- Multi-stage process control: Supports multi-stage pressure settings (e.g., pre-pressure of 20T → main pressure of 300T → holding pressure of 50T) and multi-stage temperature adjustments (e.g., 80°C → 150°C → 100°C), perfectly tailored to meet the forming requirements of various materials such as ceramics, carbon fiber, and polymers.

- Structural Flexibility: Featuring a four-column, three-beam design, the upper and lower heating plates achieve parallelism within ±0.03mm and flatness of ±0.02mm, making it compatible with molds of various sizes—such as the 640×530mm heated surface—and enabling mold changes in under 30 minutes.

5. Broad applicability: Covers multiple industries and materials

Material compatibility: Suitable for a wide range of materials, including ceramics, metals, polymers, and composite materials (such as carbon fiber, glass fiber, and graphene), meeting the molding needs of various industries—for example, ceramic components in electronics and semiconductors, or carbon fiber parts for automotive applications.

Industry Coverage: Widely used in sectors such as electronics, semiconductors, aerospace, automotive manufacturing, medical devices, and new energy—this equipment serves as a core component of high-end manufacturing (e.g., as a key supplier to companies like Tesla, Apple, and CATL).

Summary

High-precision vacuum hot-pressing machines are the cornerstone of "high-end manufacturing," with their core value lying in maximizing the integration of "material performance" and "forming accuracy." By leveraging precise parameter control, protected vacuum environments, and intelligent operation systems, these machines enable a "zero-error" transformation—from raw materials to finished products. As new materials like carbon fiber and graphene gain widespread adoption—global demand for carbon fiber is growing at an annual rate exceeding 15%—and as industries such as electronics, semiconductors, and renewable energy continue to upgrade, high-precision vacuum hot-pressing machines will remain the "core equipment" driving "high-end manufacturing," helping more products achieve the goals of being "lightweight, high-performance, and highly consistent."

Main performance and features of the equipment:

a. High vacuum level, reaching up to 0.99 vacuum degree;

b. High temperature control accuracy of ±1°C;

c. The hot plate temperature difference can be as low as ±5°C at best;

d. The hot plate can achieve a flatness accuracy as high as ±0.03 mm;

e. Multi-stage pressure control, with a hold time set separately for each pressure stage;

f. Multiple venting function;

g. Multi-stage temperature control;

h. Scheduled heating function;

I. Menu-based save/recall functionality for product production data;

j. Three-stage pneumatic inflation function;

k. 1000-second ultra-long holding pressure function;

a. Heating methods: Optional electric heating tube or mold temperature controller heating;

b. Cooling method: Can be connected to a cooling tower or an ice water machine

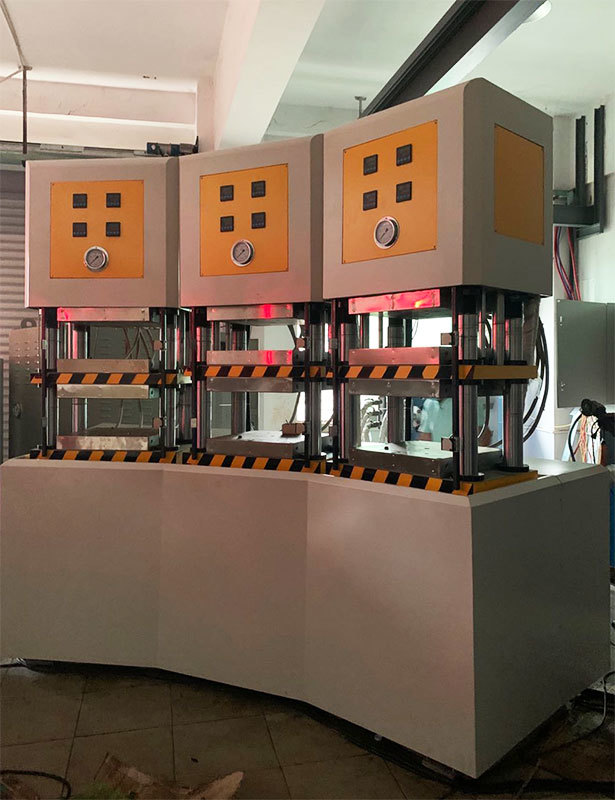

Environmental equipment

Factory

Factory 1

Factory 2

Factory 3

Factory 4

Get a Quote

Vacuum Hot Press Molding Machine

If you require custom-delivered products, Please contact us!

Category Belonging

Keywords

Related Products

High-Precision Hot-Pressing Oil Machine for the 3C Industry

-

High-Precision Hot-Pressing Oil Machine for the 3C Industry

3C electronics manufacturing: mobile phone back covers (e.g., PC+PMMA composite panels), VR/AR helmet casings, and TWS earphone back covers (requiring lightweight, sleek design, and excellent scratch resistance).

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

-

Ultra-high-precision hot pressing machine

The high-precision hot press molding machine (hereinafter referred to as the "High-Precision Machine") boasts core advantages such as positioning accuracy of ±0.01 mm, temperature control accuracy of ±1°C, and pressure accuracy of ±0.1 MPa. It focuses on the mass production of high-value, highly complex, and consistently reliable products, serving a range of strategic emerging industries.

-

High-Precision Four-Column Top-Cylinder Hot Press Molding Machine

The high-precision four-column, upper-cylinder hot press is the core equipment for "high-precision hot pressing," offering "stable four-column guidance," "precise upper-cylinder actuation," and "accurate control of temperature and pressure." These features enable it to meet the "small-size, high-precision, mass-production" requirements of advanced products such as composite materials, electronic components, and metal items.

-

High-Precision Four-Column Bottom-Cylinder Hot Press Molding Machine

The high-precision four-column, bottom-cylinder hot press is the core equipment for "upward-pressure precision molding." Its "rigid four-column structure," "stable bottom-cylinder drive," and "precise control of temperature and pressure" enable it to meet the "mass production + high-accuracy" demands across multiple industries, including rubber, composite materials, metals, and eco-friendly products.

Multi-layer four-column composite material hot press molding machine

-

High-Precision Four-Column Multi-Layer Composite Material Hot Press Molding Machine

The high-precision four-column multi-layer hot press molding machine is a key piece of equipment for mass-producing multi-material components, combining the "stability of the four-column structure," the "efficiency of the multi-layer heating plates," and the "reliability of high-precision control."

-

Multilayer Composite Hot Press Molding Machine

The multi-layer composite hot press is a key piece of equipment for the mass production of multi-material components, combining the "stability of a four-column structure," the "efficiency of multi-layer heating plates," and the "reliability of high-precision control."

Multi-layer Frame-Type Composite Material Hot Press Molding Machine

-

Frame-type Multi-layer Composite Material Hot Press Molding Machine / Hot Press

Primarily suited for the thermoset molding processes of composite material sheets such as carbon fiber and glass fiber, as well as for the compression molding of 3D structural components. Specifically applied in the thermoset processing of composite parts used in automotive accessories, sports equipment, mobile phone components, and other 3C electronics industry products.

-

Frame-type Composite Material Hot Press Molding Machine / Hot Press

The frame-type multi-layer composite material hot-pressing machine is the "core equipment" for large-scale production of high-end composites, with its "stable frame structure," "efficient multi-layer design," and "reliable high-precision control," making it a critical support for lightweight yet high-strength products in industries such as aerospace, automotive manufacturing, and sports equipment.

Closed-Loop High-Temperature Vacuum Hot Press Machine

-

Vacuum Multi-Layer Hot Press Molding Machine

This model is primarily used in the production process of products requiring exceptionally high quality, particularly those made using carbon fiber or glass fiber compression molding. Both the molds and materials are cured and shaped under vacuum conditions at elevated temperatures, ensuring that the final products are free from defects such as air bubbles. Additionally, it is also suitable for thermocompression bonding of metal materials at low temperatures—between 300 and 400 degrees Celsius—and in a vacuum environment, effectively preventing oxidation during the process.

-

Vacuum High-Temperature Multi-Layer Hot Pressing Machine

The core value of the high-temperature vacuum hot-pressing machine lies in achieving high-performance material molding through the combination of "high temperature + vacuum + precise control." Its features—such as "high-temperature adaptability, ultra-high vacuum purity, and advanced precision control"—make it an indispensable piece of equipment in cutting-edge manufacturing fields like ceramics, semiconductors, and composite materials.

High-Temperature Four-Column Hot Press Machine

Large-surface Non-Standard Customized Hot-Press Molding Machine

Automatic Baking Tray Heating Molding Machine

Servo hydraulic press

Precision Servo Hydraulic Press

-

Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

-

Precision Servo Hydraulic Press

The full name of the servo hydraulic press is: Precision Intelligent CNC Servo Hydraulic Press. It features a CNC system equipped with a human-machine interface powered by a servo-driven oil pump system, enabling users to set pressing parameters and view real-time pressing data. Additionally, the system includes an integrated online inspection function for monitoring the quality of pressed products during operation.

Servo Electric Cylinder Press

Precision Stamping Equipment and Dies

Precision Hydraulic Press

-

Four-Column Precision Punching Press

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Gantry-Type Precision Punching Machine (Eight-Sided High-Precision Guidance)

The precision punching machine features an all-steel, welded frame structure that combines the benefits of precision stamping and cold pressing. It delivers high cutting accuracy and produces clean, smooth shear surfaces, enabling one-step forming of finished products directly from the stamping process.

-

Automatic Precision Hydraulic Press

The Baijun Automatic Precision Punching Hydraulic Press features an all-steel, welded frame structure that combines the benefits of precision punching and cold pressing. It delivers high punching accuracy and excellent shearing surface finish, enabling one-step stamping and forming of finished products.

-

Four-column precision hydraulic press

The Baijun Four-Column Precision Hydraulic Press features an all-steel, welded frame structure that combines the precision stamping and cold pressing capabilities, delivering high cutting accuracy and exceptionally smooth shear surfaces—enabling one-step forming of finished products.

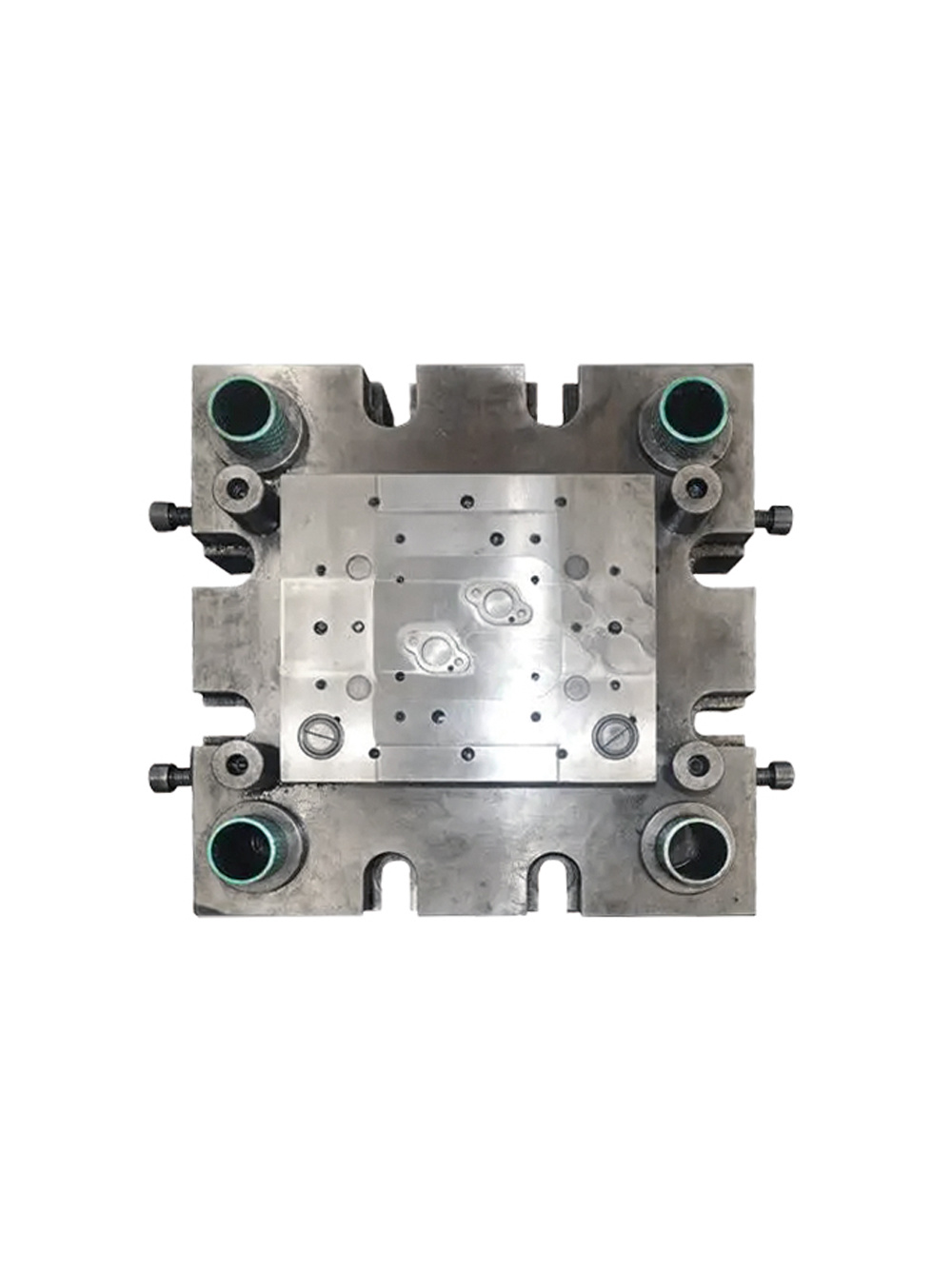

Precision Stamping Die

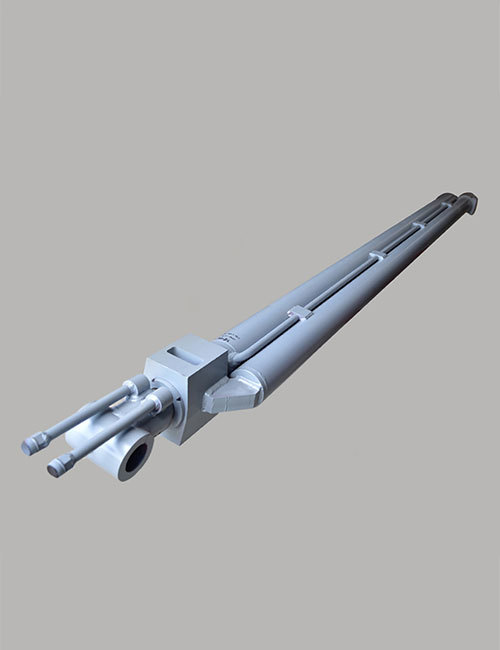

Powder-to-Shape Hydraulic Press

-

Powder Molding Hydraulic Press

-

Universal Powder Molding Machine

The Baijun Powder Forming Machine (video) features servo motor-driven operation, with centralized control provided by a PLC and human-machine interface, enabling integrated mechanical, electrical, hydraulic, and pneumatic control.

-

Automatic Hydraulic Press for Magnetic Materials

Die Casting Island Trimming Machine

Die Casting Island Trimming Machine

-

Die-casting island edge trimming hydraulic press

-

Automatic Edge-Cutting Machine for Die-Cast Parts on the Island

The Baijun Die Casting Island Internal Castings Automatic Deburring Machine / Die Casting Island Internal Castings Deburring Machine / Die-Cast Hydraulic Runner Deburring Machine is a core piece of equipment designed to complement precision die casting machines. After conducting extensive research and gathering feedback from numerous die-casting manufacturers, Baijun has launched its 7th-generation peripheral equipment for die casting islands—the Die Casting Island Internal Castings Runner Deburring Machine.

-

Die-casting trimmer

The die-casting trimmer machine features a four-column, three-plate frame structure and an advanced master-slave cylinder hydraulic circuit. It outperforms conventional hydraulic presses in terms of noise levels, speed, and power consumption, making it a highly efficient, high-speed, high-force, and environmentally friendly next-generation hydraulic press designed specifically for cutting sprues from die-cast parts. This machine is widely used across the die-casting industry.