Baijun Machinery specializes in hot pressing equipment, precision stamping equipment, and powder forming equipment.

Baijun Machinery

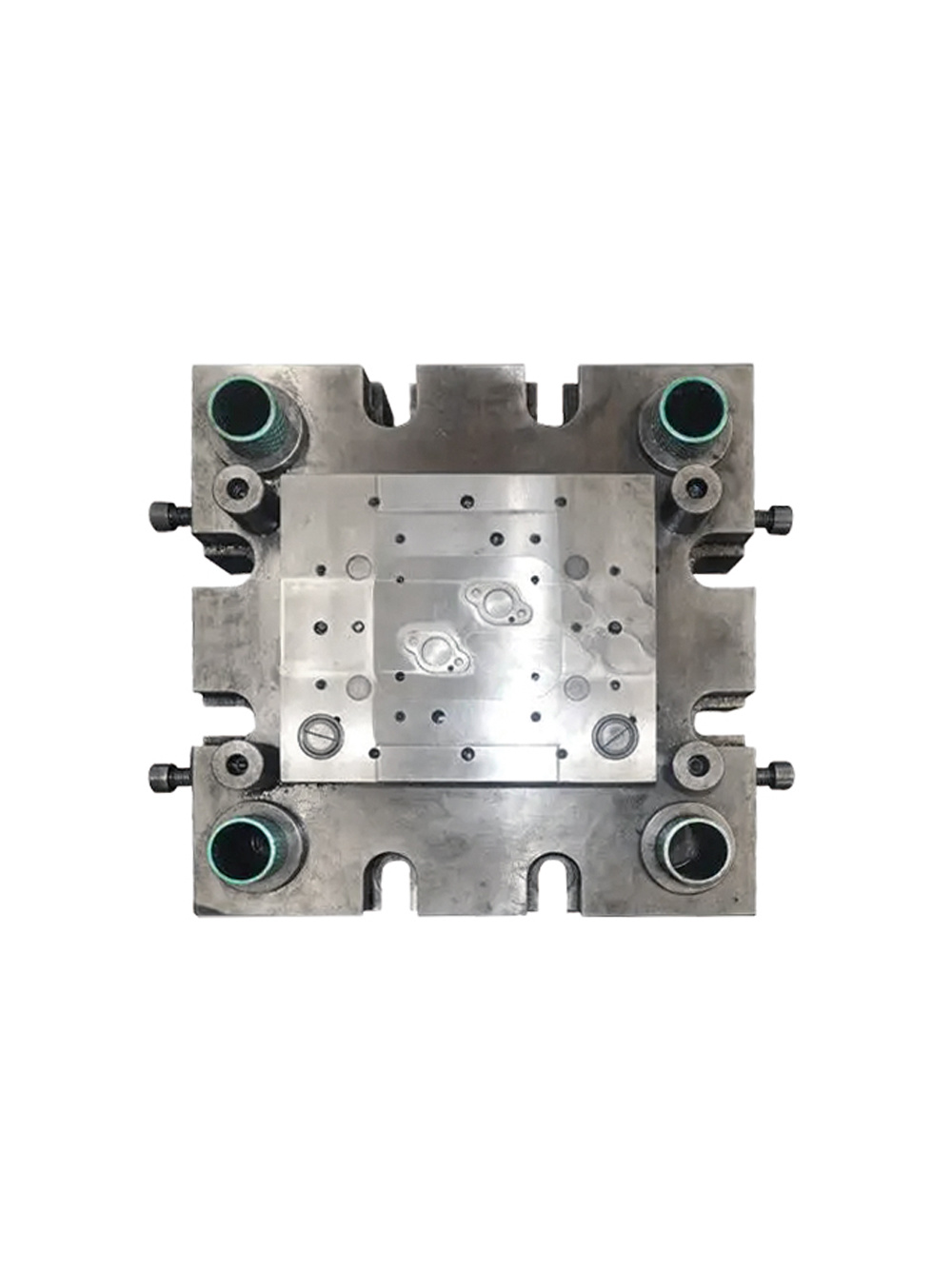

Recommend Products

Baijun Machinery customizes for you! Your needs are the source of our innovation!

Baijun Machinery

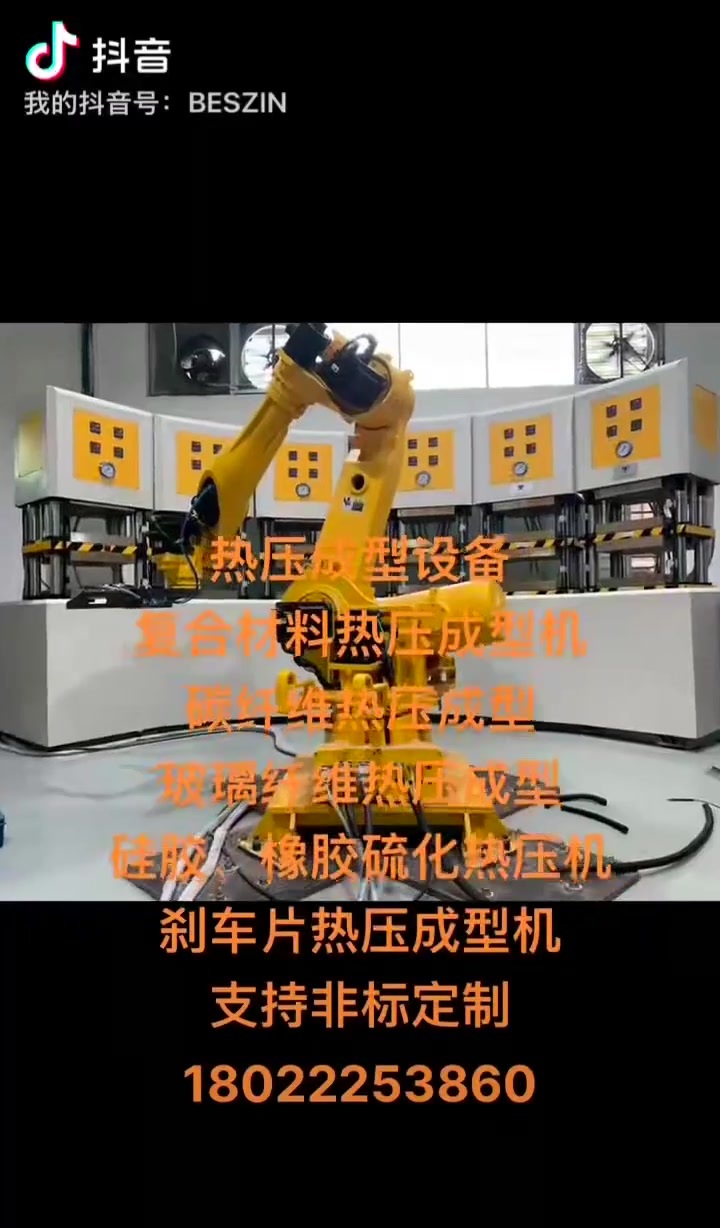

Video case

Fiberglass hot press molding machine, fiber hot press molding machine, die-casting island edge trimming machine, precision punching hydraulic press, servo hydraulic press, precision four-column hydraulic press, brake pad hydraulic press, steel backing precision punching machine, powder molding machine

Why Choose Us?

Fiberglass hot press molding machine, fiber hot press molding machine, die-casting island edge trimming machine, precision punching hydraulic press, servo hydraulic press, precision four-column hydraulic press, brake pad hydraulic press, steel backing precision punching machine, powder molding machine

Leading manufacturer—superior craftsmanship

27 years of expertise dedicated to providing customers with high-quality hydraulic equipment and intelligent production lines.

Excellent Team – Serving with Greater Care

A professional production team and quality control inspectors

Quality Assurance – Years of Deep-Rooted Product Experience

Continuously increasing investment in technological upgrades and R&D for new products

Enhance After-Sales Service – 24-Hour Response

Comprehensive after-sales service ensures customers enjoy peace of mind and convenience.

BAIJUN MACHINERY CUSTOMIZES SOLUTIONS FOR YOU!

YOUR NEEDS ARE THE SOURCE OF OUR INNOVATION!

Baijun Machinery is a manufacturer of hydraulic equipment, driven by technological innovation and dedicated to customizing non-standard hydraulic presses tailored to meet our customers' unique needs. With 27 years of experience in the design and manufacturing of specialized hydraulic machinery, we provide comprehensive technical support to ensure optimal performance for every project. Our team has conducted extensive research into precision stamping, powder metallurgy forming, and metal forging processes. Today, our products are primarily used in the manufacturing and assembly of automotive components. Key offerings include precision stamping machines, servo hydraulic presses, automated powder-forming hydraulic presses, low-pressure casting machines, as well as a wide range of general-purpose hydraulic presses and hot pressing systems—all of which can be custom-designed to perfectly align with our clients' specific requirements.

20 years of experience in non-standard hydraulic machinery design and manufacturing

Baijun Machinery's land area

Baijun Machinery Technicians and Employees

News & Media

News and Blog

Dec 25,2020

On the eve of Christmas Eve, the island-based casting sprue trimming machine—essential for Foshan Baijun's die-casting industry—gained popularity in Suzhou.

Dec 18,2020

For water-gate trimming, look no further than Foshan Baijun Die Casting's CNC trimming machine available on-site.

Dec 15,2020

Dec 11,2020

If you need a custom-designed hydraulic press

Please leave your company information and customization requirements, and our experts will get in touch with you!